- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top Methods to Optimize Ingot Casting Parameters

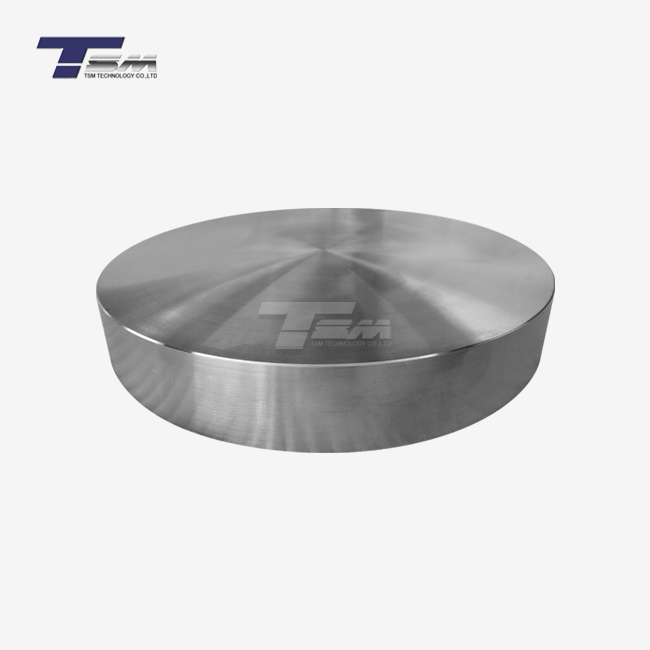

When it comes to producing superior nickel alloys and special metals, precision is non-negotiable. At TSM TECHNOLOGY, we understand that the quality of an ingot can make or break the performance of the final product, whether it's Monel, Inconel, Incoloy, or Hastelloy. Optimizing ingot casting parameters is a pivotal step in ensuring impeccable material properties, minimizing defects, and enhancing efficiency. But how do you achieve this? The key lies in fine-tuning critical variables such as temperature gradients, cooling rates, and mold design. By mastering these elements, manufacturers can unlock consistent quality and elevate their output to meet the exacting demands of precision engineering and machine shops worldwide. Let's dive into the top methods that can transform your ingot casting process into a paragon of excellence.

Mastering Temperature Control for Flawless Ingots

Temperature control is the linchpin of successful ingot casting, as it directly influences the microstructure and mechanical properties of the final alloy. Without meticulous management, you risk defects like porosity, shrinkage, or uneven grain structures. Let's explore how to refine this crucial parameter.

Precision in Melting Temperatures

The journey to a perfect ingot begins with the melting phase. Each alloy, whether it's a nickel-based superalloy or a specialty metal, has a distinct melting range. For instance, Inconel alloys typically require temperatures between 1,300°C and 1,450°C, depending on the specific grade. Deviating from this range can lead to incomplete melting or excessive energy consumption. Utilize advanced thermocouples and infrared pyrometers to monitor and maintain these temperatures within a tolerance of ±5°C. This precision ensures a homogenous molten pool, setting the stage for defect-free solidification.

Optimizing Pouring Temperatures

Once the alloy is molten, the pouring temperature becomes the next critical variable. Pouring too hot can cause turbulence in the mold, leading to gas entrapment, while pouring too cold may result in premature solidification and cold shuts. A good rule of thumb is to pour at a temperature 50°C to 100°C above the alloy's liquidus point. For Hastelloy, this might mean a pouring temperature around 1,400°C. Calibrating your equipment to achieve this balance minimizes thermal shock to the mold and promotes uniform solidification, enhancing the ingot's integrity.

Controlling Cooling Rates

The cooling rate during solidification is a decisive factor in determining grain size and phase distribution. Rapid cooling can produce fine grains, which enhance strength but may increase internal stresses. Conversely, slow cooling fosters larger grains, improving ductility but potentially compromising hardness. For nickel alloys, a controlled cooling rate of 10°C to 20°C per minute is often ideal, depending on the desired properties. Implement water-cooled molds or insulating ceramic linings to regulate this rate, ensuring the ingot achieves the optimal balance of strength and toughness for downstream applications.

Enhancing Mold Design for Superior Ingot Quality

The mold is more than just a container - it's a dynamic tool that shapes the ingot's future. A well-designed mold can mitigate defects, improve surface finish, and streamline the casting process. Let's delve into how mold design can be optimized to elevate your ingot casting outcomes.

Selecting the Right Mold Material

The choice of mold material is paramount, as it must withstand extreme temperatures while maintaining dimensional stability. For casting superior nickel alloys, graphite molds are often preferred due to their high thermal conductivity and resistance to thermal shock. Alternatively, ceramic molds can be used for alloys requiring slower cooling rates, as they provide excellent insulation. Ensure the mold material is compatible with the alloy's chemistry to prevent reactions that could degrade the ingot's surface or composition.

Incorporating Tapered Designs

Mold geometry plays a pivotal role in facilitating ingot release and minimizing defects. A tapered mold design, with a draft angle of 1° to 3°, allows for easier demolding and reduces the risk of cracking due to thermal contraction. This is particularly important for alloys like Monel alloys, which exhibit significant shrinkage during solidification. By incorporating a slight taper, you can also improve the flow of molten metal, reducing turbulence and ensuring a uniform fill.

Utilizing Advanced Coatings

Mold coatings are an often-overlooked aspect of ingot casting, yet they can dramatically enhance quality. Applying a thin layer of refractory coatings, such as zirconia or alumina, to the mold surface can prevent sticking, reduce thermal shock, and improve surface finish. These coatings also act as a barrier, minimizing chemical interactions between the mold and the molten alloy. For high-value applications, consider plasma-sprayed coatings, which offer superior durability and thermal resistance, ensuring consistent performance over multiple casting cycles.

Leveraging Advanced Monitoring and Quality Assurance

In the realm of ingot casting, what you can't measure, you can't control. Advanced monitoring and quality assurance systems are indispensable for achieving consistent, high-quality ingots. By integrating cutting-edge technology and rigorous inspection protocols, you can ensure every ingot meets the stringent demands of precision engineering.

Implementing Real-Time Sensors

Real-time monitoring is a game-changer in optimizing ingot casting parameters. Sensors embedded in the mold can track critical variables such as temperature, pressure, and vibration, providing a comprehensive picture of the casting process. For instance, a sudden spike in mold temperature might indicate an issue with cooling, while excessive vibration could signal turbulence in the melt. By analyzing this data, you can make on-the-fly adjustments, ensuring the process remains within optimal parameters. For nickel alloys, maintaining a mold temperature gradient of less than 50°C across the ingot height is crucial to prevent cracking.

Conducting Non-Destructive Testing

Once the ingot is cast, non-destructive testing (NDT) is essential to verify its internal quality. Techniques such as ultrasonic testing and X-ray radiography can detect internal defects like porosity, inclusions, or shrinkage cavities without compromising the ingot's integrity. For example, ultrasonic testing can identify voids as small as 0.5 mm, ensuring the ingot meets the exacting standards required for applications in aerospace or chemical processing. At TSM TECHNOLOGY, our rigorous NDT protocols are a cornerstone of our commitment to delivering superior alloys to our global clientele.

Establishing a Feedback Loop

Quality assurance doesn't end with testing - it's an ongoing process. Establishing a feedback loop between casting operations and quality control allows you to continuously refine your parameters. Analyze data from each casting run to identify trends, such as recurring defects or deviations in cooling rates. Use this information to adjust variables like pouring temperature or mold design, creating a cycle of continuous improvement. This approach not only enhances ingot quality but also boosts efficiency, reducing waste and energy consumption in the long run.

Conclusion

Optimizing ingot casting parameters is a multifaceted endeavor that demands precision, innovation, and a commitment to quality. By mastering temperature control, enhancing mold design, and leveraging advanced monitoring, manufacturers can produce ingots that meet the highest standards of excellence. These methods not only improve the quality of superior nickel alloys and special metals but also position your operations at the forefront of the industry. At TSM TECHNOLOGY, we're dedicated to pushing the boundaries of alloy development, ensuring our products empower precision engineering and machine shops worldwide.

Contact Us

For more information on our superior alloy casting capabilities and how we can support your precision engineering needs, please don't hesitate to reach out to us at info@tsmnialloy.com. At TSM TECHNOLOGY, we're committed to pushing the boundaries of alloy production to meet your most demanding applications.

References

Campbell, J. (2015). Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design. Butterworth-Heinemann.

Stefanescu, D. M. (2015). Science and Engineering of Casting Solidification. Springer.

Flemings, M. C. (1974). Solidification Processing. McGraw-Hill.

ASM International. (1990). ASM Handbook, Volume 15: Casting. ASM International.

Kurz, W., & Fisher, D. J. (1998). Fundamentals of Solidification. Trans Tech Publications.

Grong, Ø. (1997). Metallurgical Modelling of Welding and Casting Processes. Institute of Materials.

Learn about our latest products and discounts through SMS or email

_1739072401467.webp)