- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is VIM + ESR? Introducing the Smelting Method of Superalloys

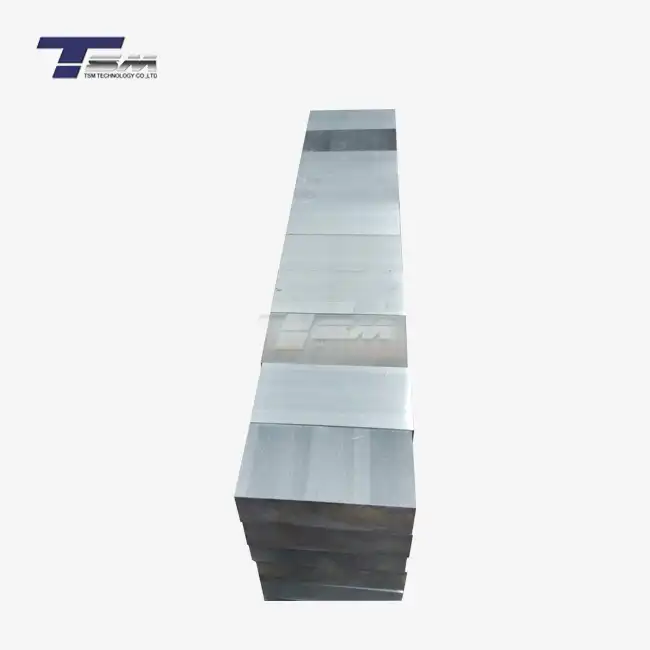

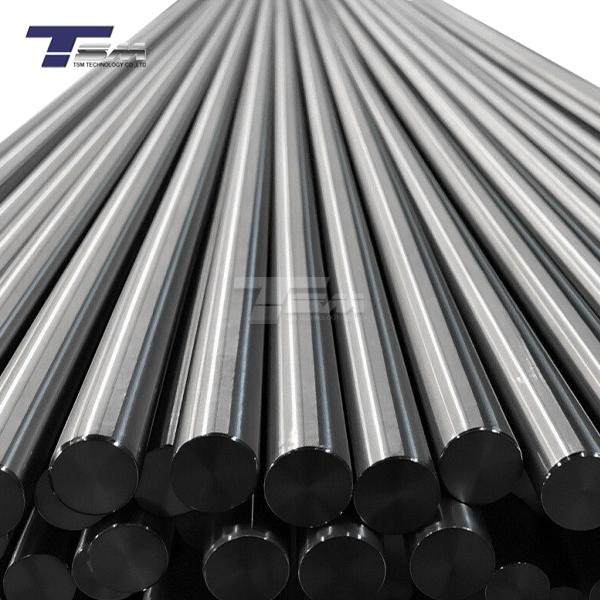

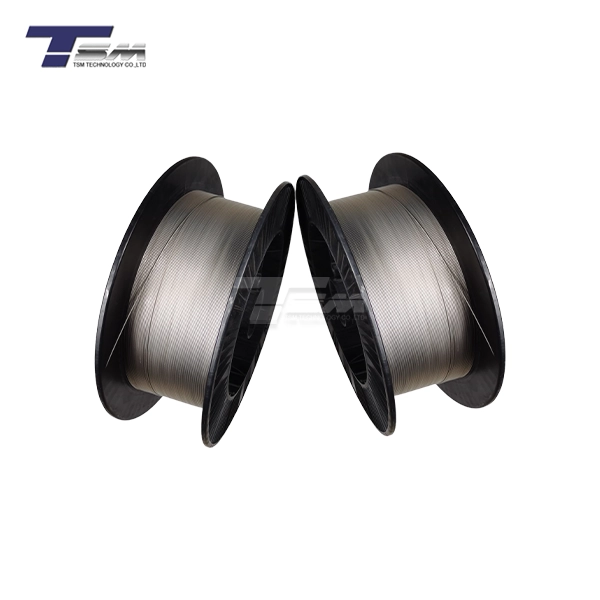

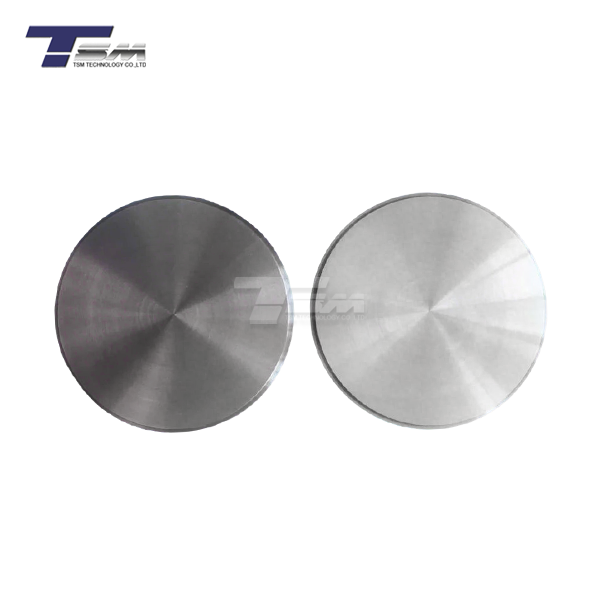

When it comes to crafting high-performance materials for industries like aerospace, energy, and precision engineering, the smelting process is the backbone of quality. VIM + ESR, or Vacuum Induction Melting combined with Electroslag Remelting, is a sophisticated duo of techniques used to produce superalloys - exceptional materials designed to withstand extreme conditions. These methods ensure the creation of superior alloys, such as Monel, Inconel, Incoloy, and Hastelloy, by eliminating impurities and enhancing structural integrity. At TSM TECHNOLOGY, we rely on these advanced processes to deliver top-tier nickel alloys and special metals to our global clientele, ensuring unparalleled performance in the most demanding applications.

Unveiling the Science Behind VIM + ESR Smelting

The production of superalloys is no ordinary feat - it demands precision, expertise, and cutting-edge technology. VIM + ESR represents the pinnacle of metallurgical innovation, ensuring that materials meet the stringent requirements of industries worldwide. Let's dive into the intricacies of these processes and explore why they are indispensable for creating high-quality alloys.

What is Vacuum Induction Melting (VIM)?

Vacuum Induction Melting is a process that takes place in a vacuum environment, where raw materials are melted using electromagnetic induction. This method is ideal for producing alloys with exceptional purity, as the vacuum eliminates atmospheric contaminants like oxygen and nitrogen, which can compromise material quality. By melting metals in a controlled setting, VIM ensures a homogenous composition, free from inclusions and defects. This is particularly crucial for nickel-based alloys, which must endure high temperatures and corrosive environments without faltering.

Understanding Electroslag Remelting (ESR)

Following VIM, Electroslag Remelting steps in to refine the alloy further. ESR involves remelting the VIM-produced ingot by passing an electric current through a slag layer, which acts as a purifying medium. This process removes residual impurities, such as sulfur and non-metallic inclusions, while enhancing the alloy's microstructure. The result is a material with superior mechanical properties, including enhanced strength, fatigue resistance, and ductility. ESR is especially vital for applications where reliability under extreme stress is non-negotiable, such as in turbine blades or chemical processing equipment.

Why Combine VIM and ESR?

The synergy of VIM and ESR is what sets superalloys apart from conventional materials. While VIM ensures a pristine starting point by producing a clean, uniform ingot, ESR takes it a step further by refining the microstructure and eliminating microscopic flaws. This dual approach is essential for manufacturing alloys that meet the rigorous standards of industries like aerospace, where even the slightest imperfection can lead to catastrophic failure. At TSM TECHNOLOGY, we harness this powerful combination to deliver materials that excel in performance and longevity, solidifying our position as a trusted global supplier of nickel alloys and special metals.

The Role of VIM + ESR in Crafting High-Performance Superalloys

Superalloys are the unsung heroes of modern engineering, powering everything from jet engines to chemical reactors. The VIM + ESR smelting method is the cornerstone of their production, enabling the creation of materials that thrive under punishing conditions. Let's explore how this process contributes to the exceptional properties of superalloys and why it matters for industries worldwide.

Achieving Unmatched Purity and Consistency

Purity is the hallmark of a superior alloy, and the VIM + ESR process excels in delivering it. By conducting the initial melting in a vacuum, VIM prevents the introduction of gases that could weaken the material. The subsequent ESR stage refines the alloy even further, ensuring a uniform composition and eliminating inclusions that could act as stress concentrators. This meticulous approach results in alloys with consistent properties across every batch, a critical factor for industries that demand reliability, such as precision engineering and machine shops.

Enhancing Mechanical Properties for Extreme Environments

Superalloys are renowned for their ability to perform in environments where ordinary metals would fail - think scorching temperatures, corrosive chemicals, and immense mechanical stress. The VIM + ESR process plays a pivotal role in achieving these capabilities by optimizing the alloy's microstructure. The refined grain structure and reduced defect density enhance properties like creep resistance, fatigue strength, and toughness. This makes alloys like Inconel and Hastelloy ideal for applications in aerospace components, power generation turbines, and offshore oil platforms, where durability is paramount.

Meeting Stringent Industry Standards

Industries that rely on superalloys operate under strict regulatory and performance standards, and the VIM + ESR process ensures compliance. The elimination of impurities and the enhancement of material properties mean that alloys produced through this method consistently meet or exceed specifications set by organizations like ASTM and ASME. At TSM TECHNOLOGY, our commitment to quality is unwavering - we subject every product to rigorous inspection by our professional team, ensuring that our clients receive materials that perform flawlessly in their applications, no matter where they are in the world.

Why TSM TECHNOLOGY Trusts VIM + ESR for Superior Alloys?

At TSM TECHNOLOGY, our mission is to provide the highest-quality nickel alloys and special metals to the global market, and the VIM + ESR smelting method is integral to achieving this goal. Our dedication to innovation, reliability, and excellence has made us a trusted partner for precision engineering industries and machine shops worldwide. Here's why we place our trust in this advanced smelting technique and how it benefits our clients.

Delivering Tailored Solutions for Diverse Industries

The versatility of the VIM + ESR process allows us to produce a wide range of alloys, each tailored to meet the specific needs of different industries. Whether it's Monel for marine applications, Inconel for aerospace components, or Hastelloy for chemical processing, our materials are engineered to deliver optimal performance. The precision of VIM + ESR enables us to control alloy composition and properties with exactitude, ensuring that our clients receive products that align perfectly with their technical requirements, no matter the complexity of the application.

Pioneering Innovation in Alloy Development

As a forward-thinking supplier, we are constantly pushing the boundaries of material science to bring advanced solutions to the market. The VIM + ESR process is a cornerstone of our research and development efforts, allowing us to experiment with new alloy formulations and improve existing ones. This commitment to innovation ensures that our clients have access to cutting-edge materials that give them a competitive edge in their respective fields. Our 14-year journey, which began in Hong Kong in 2011, is a testament to our relentless pursuit of excellence in the realm of nickel alloys and special metals.

Ensuring Quality Through Rigorous Standards

Quality is at the heart of everything we do at TSM TECHNOLOGY. The VIM + ESR process is just one part of our comprehensive quality assurance system, which includes strict controls and inspections at every stage of production. Our professional inspectors meticulously evaluate each product to ensure it meets our exacting standards, providing our clients with the confidence that they are receiving materials of unparalleled quality. This dedication to precision and reliability has earned us a reputation as a leader in the global market for high-performance alloys.

Conclusion

The VIM + ESR smelting method is a game-changer in the world of superalloys, enabling the production of materials that excel in the most challenging environments. By combining the purity of Vacuum Induction Melting with the refinement of Electroslag Remelting, this process delivers alloys with exceptional properties, making it indispensable for industries worldwide. At TSM TECHNOLOGY, we leverage this advanced technique to provide our global clients with top-tier nickel alloys and special metals, ensuring performance, reliability, and innovation in every product.

Contact Us

For more information about our superior alloy products and services, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect alloy solution for your specific needs.

References

Reed, R.C. The Superalloys: Fundamentals and Applications. Cambridge University Press, 2006.

Donachie, M.J., and Donachie, S.J. Superalloys: A Technical Guide. ASM International, 2002.

Sims, C.T., Stoloff, N.S., and Hagel, W.C. Superalloys II: High-Temperature Materials for Aerospace and Industrial Power. Wiley-Interscience, 1987.

Pollock, T.M., and Tin, S. "Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure, and Properties." Journal of Propulsion and Power, Vol. 22, No. 2, 2006.

Geddes, B., Leon, H., and Huang, X. Superalloys: Alloying and Performance. ASM International, 2010.

Loria, E.A. "Advances in Superalloy Processing and Applications." Journal of Metals, Vol. 41, No. 7, 1989.

Learn about our latest products and discounts through SMS or email