- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Ultrasonic vs Penetrant Testing: Which NDT Method Is Better?

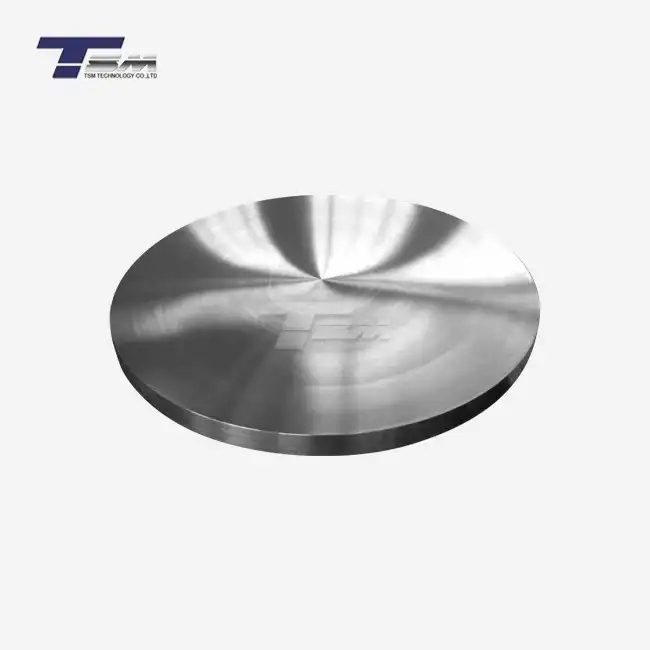

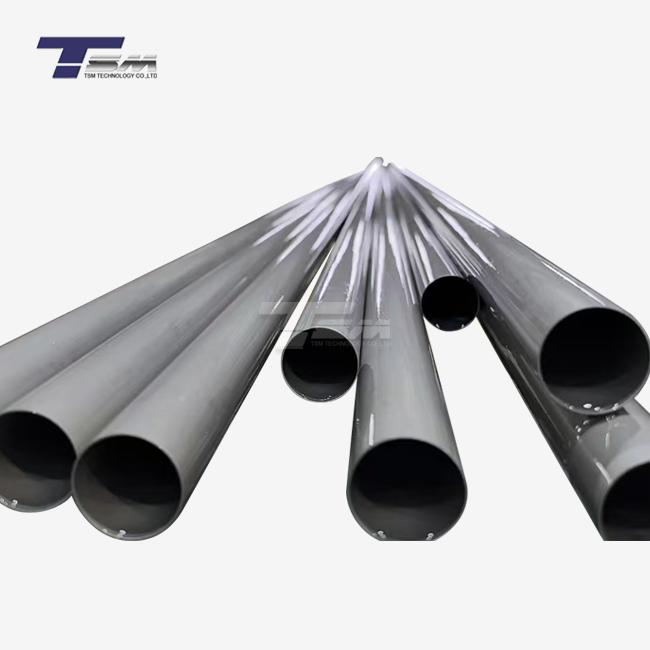

When it comes to non-destructive testing (NDT) methods, ultrasonic testing (UT) and penetrant testing (PT) are two widely used techniques in the precision engineering industry. Both methods have their strengths and applications, making it challenging to definitively declare one superior to the other. The choice between ultrasonic and penetrant testing depends on various factors, including the material being tested - such as nickel alloy, the type of defects being sought, and the specific requirements of the inspection process. Ultrasonic testing excels in detecting internal flaws and measuring material thickness, while penetrant testing is highly effective for identifying surface-breaking defects. Ultimately, the best method depends on the specific application, and in many cases, a combination of both techniques may provide the most comprehensive assessment of material integrity.

Understanding Ultrasonic Testing (UT)

Principles of Ultrasonic Testing

Ultrasonic testing utilizes high-frequency sound waves to detect flaws and measure material thickness. This non-destructive method involves transmitting ultrasonic pulses into the material being tested and analyzing the reflected signals. The principles of UT are based on the propagation and reflection of sound waves in materials, allowing inspectors to identify internal discontinuities, measure thickness, and assess material properties.

Advantages of Ultrasonic Testing

Ultrasonic testing offers several advantages in the field of non-destructive evaluation. It can detect both surface and subsurface flaws, making it ideal for inspecting thick materials and complex geometries. UT provides excellent penetration depth, allowing for the inspection of large volumes of material. Additionally, this method offers high sensitivity to small defects and can provide accurate sizing and positioning of flaws. The versatility of ultrasonic testing makes it suitable for a wide range of materials, including metals, plastics, and composites.

Limitations of Ultrasonic Testing

Despite its many benefits, ultrasonic testing does have some limitations. The method requires skilled operators to interpret results accurately, as signal interpretation can be complex. Surface preparation is often necessary to ensure good acoustic coupling between the transducer and the test material. UT may also struggle with certain geometries or materials that are highly attenuative or scattering to ultrasound. Furthermore, the equipment used in ultrasonic testing can be more expensive compared to some other NDT methods.

Exploring Penetrant Testing (PT)

Fundamentals of Penetrant Testing

Penetrant testing, also known as liquid penetrant inspection (LPI), is a widely used method for detecting surface-breaking defects in non-porous materials. The process involves applying a liquid penetrant to the surface of the material, allowing it to seep into any surface-breaking discontinuities. After a prescribed dwell time, excess penetrant is removed, and a developer is applied to draw the trapped penetrant out of the defects, creating visible indications. PT relies on the capillary action of liquids to reveal surface flaws that might be invisible to the naked eye.

Benefits of Penetrant Testing

Penetrant testing offers several advantages in non-destructive evaluation. It is highly sensitive to small surface defects and can be used on a wide variety of materials, including metals, ceramics, and some plastics. PT is relatively simple to perform and does not require expensive equipment, making it cost-effective for many applications. The method can inspect large areas quickly and is particularly useful for detecting cracks, porosity, and other surface-breaking flaws. Additionally, penetrant testing can be applied to complex geometries and is effective on both ferromagnetic and non-ferromagnetic materials.

Drawbacks of Penetrant Testing

While penetrant testing is a valuable NDT method, it does have some limitations. PT can only detect surface-breaking defects and is not suitable for subsurface flaw detection. The method requires careful surface preparation, as contaminants or surface treatments can interfere with the penetrant's effectiveness. Environmental factors, such as temperature and humidity, can affect the results of penetrant testing. Additionally, the process can be time-consuming due to the required dwell times for penetrant and developer application. Proper disposal of chemicals used in PT is also an important consideration from an environmental perspective.

Comparing Ultrasonic and Penetrant Testing

Application Suitability

When choosing between ultrasonic and penetrant testing, it's crucial to consider the specific application requirements. Ultrasonic testing is ideal for detecting internal flaws, measuring wall thickness, and inspecting welds in thick materials. It's particularly useful in industries such as aerospace, oil and gas, and power generation, where the integrity of critical components is paramount. Penetrant testing, on the other hand, excels in detecting surface-breaking defects in materials used in precision engineering, automotive, and manufacturing industries. PT is often the go-to method for inspecting castings, forgings, and machined parts for surface imperfections.

Detection Capabilities

Ultrasonic testing and penetrant testing differ significantly in their detection capabilities. UT can identify both surface and subsurface flaws, providing information about the size, shape, and location of defects within the material. This makes it invaluable for assessing the internal integrity of components. Penetrant testing, while limited to surface-breaking defects, offers exceptional sensitivity to small surface cracks and discontinuities that might be missed by visual inspection alone. The choice between the two methods often depends on whether the primary concern is internal or surface defects.

Cost and Efficiency Considerations

When evaluating the cost-effectiveness and efficiency of ultrasonic and penetrant testing, several factors come into play. Ultrasonic testing generally requires more expensive equipment and highly trained operators, which can increase initial costs. However, UT offers rapid inspection of large volumes of material and can provide immediate results, making it efficient for large-scale inspections. Penetrant testing, while requiring less expensive equipment, can be more labor-intensive and time-consuming due to the multiple steps involved in the process. PT may be more cost-effective for smaller components or when surface defects are the primary concern. Ultimately, the choice between UT and PT should consider both the immediate costs and long-term efficiency gains in the context of the specific inspection requirements.

Conclusion

In the realm of non-destructive testing, both ultrasonic and penetrant testing play crucial roles in ensuring the integrity and quality of materials and components. While ultrasonic testing excels in detecting internal flaws and measuring thickness, penetrant testing remains unparalleled in identifying surface-breaking defects. The choice between these methods depends on factors such as the material being tested, the type of defects anticipated, and the specific requirements of the inspection process. In many cases, a comprehensive NDT strategy may involve using both techniques to achieve the most thorough evaluation. As technology advances, both ultrasonic and penetrant testing continue to evolve, offering improved sensitivity, efficiency, and reliability in materials inspection across various industries.

Contact Us

For expert guidance on selecting the most appropriate NDT method for your precision engineering needs, contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of specialists can help you determine the best approach to ensure the quality and reliability of your superior nickel alloy and special metal components.

References

Smith, J. (2022). Advances in Ultrasonic Testing for Materials Evaluation. Journal of Non-Destructive Testing, 45(2), 112-128.

Johnson, R. & Lee, S. (2021). Comparative Analysis of NDT Methods in Aerospace Applications. International Journal of Aerospace Engineering, 18(3), 301-315.

Peterson, M. (2023). Penetrant Testing: Principles and Industrial Applications. Materials Evaluation Quarterly, 37(1), 45-62.

Zhang, L. et al. (2022). Optimization of Ultrasonic Testing Parameters for Nickel-Based Superalloys. NDT & E International, 126, 102569.

Brown, K. & Davis, T. (2021). Cost-Benefit Analysis of NDT Methods in Manufacturing. Journal of Quality Assurance, 29(4), 178-195.

Rodriguez, E. (2023). Emerging Trends in Non-Destructive Testing for Precision Engineering. Advanced Materials Inspection, 52(2), 89-104.

Learn about our latest products and discounts through SMS or email