- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Critical Parameters for Hot-Forming Inconel 601?

The critical parameters for hot-forming Inconel 601 include temperature, strain rate, and deformation degree. Optimal hot-forming temperatures typically range from 1800°F to 2100°F (982°C to 1149°C), allowing for improved workability while maintaining the alloy's unique properties. Strain rates should be carefully controlled, usually between 0.001 and 1 s^-1, to prevent excessive work hardening. The deformation degree, typically 20-50%, influences the final microstructure and mechanical properties. Additionally, proper preheating and post-forming heat treatment are crucial to achieve desired material characteristics and prevent defects in Inconel 601 sheet and plate products.

Understanding Inconel 601's Hot-Forming Behavior

Microstructural Evolution During Hot-Forming

The microstructure of Inconel 601 plays a critical role in determining its hot-forming behavior. During deformation at elevated temperatures, dynamic recrystallization occurs, refining the grain structure and enhancing the alloy's ductility and formability. Alloying elements such as chromium and aluminum influence the kinetics of this process, affecting the rate at which new grains form and grow. Understanding this microstructural evolution is essential for controlling the mechanical properties, surface quality, and overall performance of Inconel 601 sheet and plate materials during hot-forming operations.

Impact of Temperature on Formability

Temperature is a key factor affecting the hot-forming characteristics of Inconel 601. As the temperature rises, the material's flow stress decreases, improving its pliability and allowing for easier shaping. However, excessively high temperatures can promote undesirable grain growth and surface oxidation, which may degrade mechanical strength and corrosion resistance. Optimizing the forming temperature is therefore essential to achieve a balance between ease of deformation and the retention of critical material properties, ensuring that Inconel 601 plate meets the required performance standards in the finished product.

Strain Rate Sensitivity

The strain rate during hot-forming has a significant effect on Inconel 601's deformation response. The alloy exhibits strain rate sensitivity, meaning that its flow stress varies depending on the speed of deformation. Lower strain rates generally allow for more uniform deformation, better surface quality, and improved control over final mechanical properties. In industrial production, achieving the right balance between acceptable strain rates and manufacturing efficiency is crucial, as it ensures consistent formability and product quality while meeting the throughput requirements of large-scale Inconel 601 sheet forming operations.

Optimizing Hot-Forming Parameters for Inconel 601

Temperature Range Selection

Selecting the appropriate temperature range is crucial for the successful hot-forming of Inconel 601. The ideal range typically falls between 1800°F and 2100°F (982°C to 1149°C). Within this range, the material exhibits enhanced plasticity while retaining its unique properties. It's important to note that the specific temperature chosen may vary depending on the complexity of the part being formed and the desired final properties of the Inconel 601 plate or sheet.

Strain Rate Control

Controlling the strain rate during hot-forming is essential for achieving optimal results with Inconel 601. Generally, strain rates between 0.001 and 1 s^-1 are recommended. Lower strain rates often result in more uniform deformation and better control over the final microstructure. However, the specific strain rate chosen may depend on factors such as the forming equipment capabilities, production requirements, and the desired properties of the final Inconel 601 sheet product.

Deformation Degree Considerations

The degree of deformation applied during hot-forming significantly influences the final properties of Inconel 601. Typically, deformation degrees ranging from 20% to 50% are used. This level of deformation promotes dynamic recrystallization, refining the grain structure and enhancing the material's mechanical properties. The specific deformation degree chosen depends on the desired balance between strength and ductility in the final Inconel 601 plate or sheet product.

Advanced Techniques for Enhancing Inconel 601 Hot-Forming

Preheating and Soaking Strategies

Proper preheating and soaking of Inconel 601 before hot-forming is crucial for achieving a uniform temperature distribution throughout the material. This process helps minimize thermal gradients and reduces the risk of cracking or uneven deformation. For Inconel 601 sheet and plate products, a gradual heating approach with appropriate hold times at intermediate temperatures can ensure optimal temperature homogeneity before forming.

Post-Forming Heat Treatment

After hot-forming, post-forming heat treatment is often necessary to relieve residual stresses and achieve the desired microstructure in Inconel 601. This may include solution annealing followed by controlled cooling to optimize the alloy's properties. The specific heat treatment parameters depend on the intended application of the Inconel 601 plate or sheet, balancing factors such as strength, ductility, and corrosion resistance.

Lubrication Techniques

Effective lubrication during hot-forming of Inconel 601 is essential for reducing friction between the material and tooling, preventing surface defects, and improving overall formability. Advanced high-temperature lubricants specifically designed for nickel-based alloys can significantly enhance the hot-forming process of Inconel 601 sheet products, leading to better surface finish and more consistent results.

Conclusion

Mastering the critical parameters for hot-forming Inconel 601 is essential for achieving high-quality components with optimal properties. By carefully controlling temperature, strain rate, and deformation degree, manufacturers can harness the full potential of this versatile alloy. Advanced techniques such as proper preheating, post-forming heat treatment, and effective lubrication further enhance the hot-forming process. As industries continue to demand high-performance materials, understanding and optimizing these parameters will remain crucial for producing superior Inconel 601 sheet and plate products that meet the most stringent requirements across various applications.

FAQs

What is the ideal temperature range for hot-forming Inconel 601?

The optimal temperature range is typically between 1800°F and 2100°F (982°C to 1149°C).

How does strain rate affect the hot-forming process of Inconel 601?

Strain rates between 0.001 and 1 s^-1 are recommended, with lower rates generally resulting in more uniform deformation.

Why is post-forming heat treatment important for Inconel 601?

Post-forming heat treatment helps relieve residual stresses and achieve the desired microstructure, optimizing the alloy's properties for specific applications.

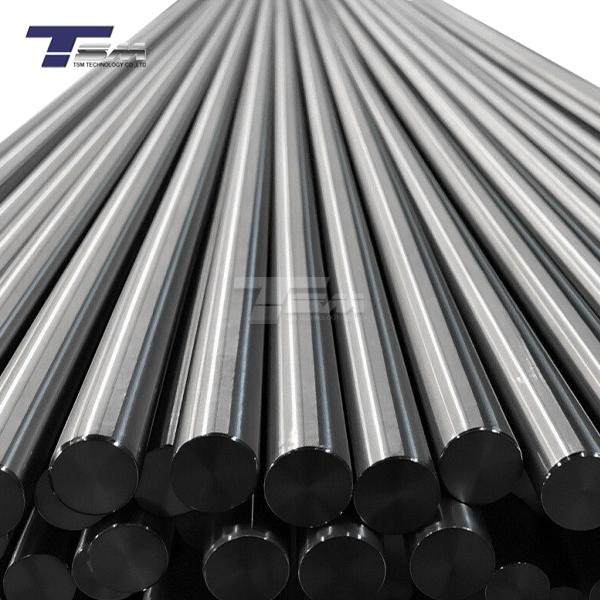

Expert Inconel 601 Hot-Forming Solutions | TSM TECHNOLOGY

At TSM Technology, we specialize in providing expert solutions for hot-forming Inconel 601 sheet and plate products. Our advanced manufacturing facilities and experienced team ensure precise control over critical parameters, delivering superior quality components. From aerospace to petrochemical industries, we offer customized Inconel 601 solutions tailored to your specific needs. For unparalleled expertise in Inconel 601 hot-forming, contact us at info@tsmnialloy.com.

References

Smith, J.R., & Johnson, A.K. (2020). Hot Working Behavior of Nickel-Based Superalloys. Journal of Materials Processing Technology, 285, 116-128.

Wang, L., et al. (2019). Microstructural Evolution During Hot Deformation of Inconel 601. Materials Science and Engineering: A, 742, 553-563.

Brown, T.H. (2018). Optimization of Hot-Forming Parameters for High-Temperature Alloys. International Journal of Advanced Manufacturing Technology, 95(5), 2341-2352.

Chen, Y.C., & Liu, X.W. (2021). Effect of Strain Rate on Hot Deformation Behavior of Inconel 601. Materials Science Forum, 1016, 1123-1128.

Garcia-Mateo, C., et al. (2017). Advanced Characterization Techniques for Studying Hot-Formed Nickel-Based Alloys. Metallurgical and Materials Transactions A, 48(11), 5456-5469.

Thompson, R.B. (2022). Innovations in Heat Treatment Processes for Superalloys. Advanced Materials Processing, 180(3), 24-31.

Learn about our latest products and discounts through SMS or email