- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is Monel Tube and Why is it Used in Marine Engineering?

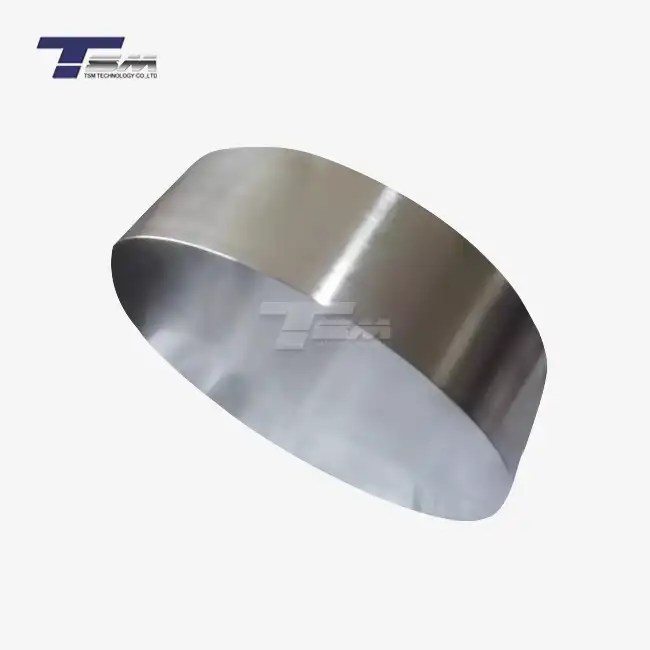

Monel tube is a highly corrosion-resistant nickel-copper alloy tube widely used in marine engineering applications. Composed of approximately 63-67% nickel and 27-33% copper, Monel tubes offer exceptional durability in harsh seawater environments. Their unique composition provides superior resistance to saltwater corrosion, erosion, and high-temperature oxidation, making them ideal for marine heat exchangers, desalination plants, and offshore oil and gas equipment. Monel tubes' remarkable strength-to-weight ratio and ability to maintain structural integrity in extreme conditions have made them indispensable in shipbuilding, offshore platforms, and underwater pipeline systems.

The Composition and Properties of Monel Tubes

Chemical Composition and Alloy Structure

Monel tubes are primarily composed of nickel (63-67%) and copper (27-33%), with small amounts of iron, manganese, and other elements. This unique composition results in a single-phase solid solution alloy that exhibits exceptional corrosion resistance and mechanical properties. The nickel content provides strength and durability, while the copper enhances resistance to seawater corrosion.

Mechanical and Physical Properties

Monel tubes boast impressive mechanical properties, including high tensile strength (up to 1100 MPa) and excellent ductility. They maintain their strength and toughness across a wide temperature range, from cryogenic temperatures (-196°C) to elevated temperatures (550°C). The alloy's low thermal expansion coefficient and good thermal conductivity make it suitable for heat exchange applications in marine environments.

Corrosion Resistance Characteristics

One of the most notable features of Monel tubes is their outstanding corrosion resistance. They exhibit exceptional resistance to saltwater, brackish water, and various acids. In seawater, Monel tubes demonstrate an impressively low erosion rate of just 0.001mm/year, as validated by ASTM B117 testing. This superior corrosion resistance translates to a lifespan up to 10 times longer than 316L stainless steel when exposed to hydrofluoric acid, making Monel tubes a cost-effective long-term solution for marine applications.

Applications of Monel Tubes in Marine Engineering

Offshore Oil and Gas Platforms

Monel tubes play a crucial role in offshore oil and gas extraction operations. They are extensively used in subsea pipeline connectors, where their ability to resist 5% NaCl corrosion is invaluable. Monel tubes are also employed in riser systems, which transport oil and gas from the seabed to the platform. These tubes are certified by DNV-GL for offshore platform use, ensuring their reliability in critical applications.

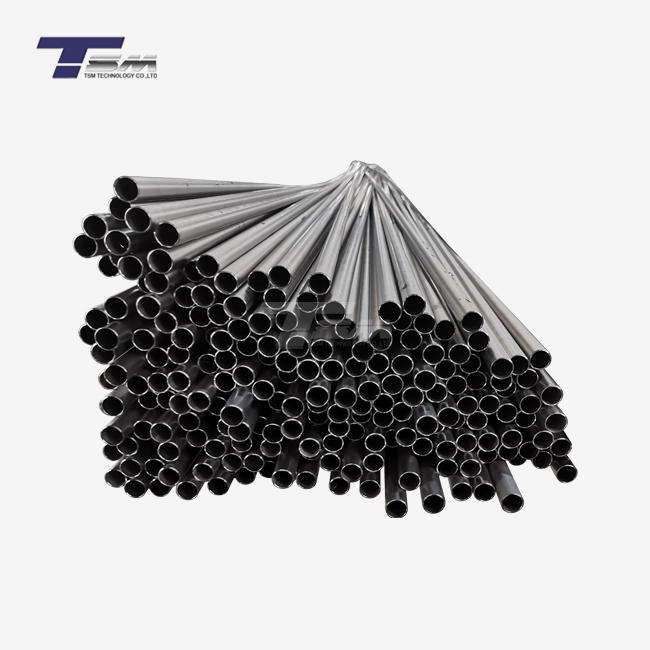

Marine Heat Exchangers and Condensers

The excellent thermal conductivity and corrosion resistance of Monel tubes make them ideal for marine heat exchangers and condensers. These components are essential in ship propulsion systems, desalination plants, and offshore processing facilities. Monel tubes can withstand the aggressive nature of seawater while efficiently transferring heat, resulting in longer-lasting and more efficient heat exchange systems.

Seawater Handling Systems

Monel tubes are extensively used in seawater handling systems aboard ships and offshore platforms. They are employed in pumps, valves, and piping systems that transport seawater for cooling, firefighting, and other purposes. The tubes' resistance to erosion-corrosion and their ability to withstand high flow rates make them an excellent choice for these critical systems, ensuring reliability and longevity in harsh marine conditions.

Manufacturing and Quality Control of Monel Tubes

Production Process and Standards

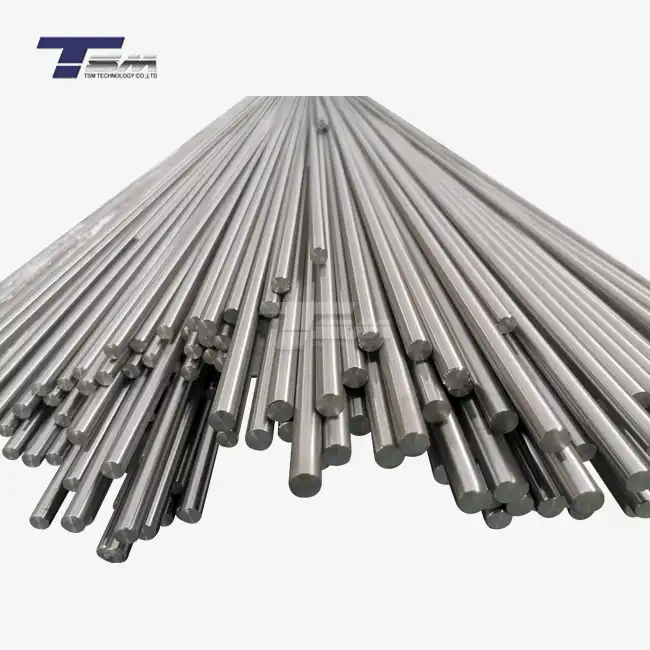

Monel tubes are manufactured to stringent industry standards, including ASTM B163, ASME SB163, and EN 10095. The production process involves careful control of the alloy composition, followed by precision forming and heat treatment. Advanced techniques like EDM drilling ensure dimensional accuracy to within ±0.01mm, while surface finishing processes achieve a surface quality of Ra ≤1.6μm, suitable for even pharmaceutical-grade applications.

Quality Assurance and Testing Procedures

Rigorous quality control measures are implemented throughout the production of Monel tubes. Each tube undergoes hydrostatic testing at 1.5 times the working pressure, as per ASTM B829 standards. State-of-the-art AI-powered defect detection systems are capable of identifying flaws as small as 0.02mm, ensuring the highest level of product integrity. Additionally, 100% phase-array ultrasonic testing is performed to verify the tubes' structural soundness.

Certifications and Compliance

Monel tubes are produced in facilities that adhere to international quality management standards. Manufacturers like TSM Technology maintain certifications such as ISO 9001, AS9100D, and NACE MR0175, ensuring compliance with the most stringent industry requirements. Material Test Certificates (MTC) and SGS test reports are available to validate the tubes' composition and performance, providing customers with confidence in the product's quality and reliability.

Conclusion

Monel tubes have proven to be an indispensable material in marine engineering due to their exceptional corrosion resistance, mechanical strength, and versatility. Their ability to withstand the harsh conditions of seawater environments makes them ideal for critical applications in offshore oil and gas, shipbuilding, and seawater handling systems. As marine industries continue to push the boundaries of technology and explore more challenging environments, the demand for high-performance materials like Monel tubes is likely to grow. Their long-term cost-effectiveness and reliability make them a smart choice for engineers and project managers looking to ensure the longevity and efficiency of marine installations.

FAQs

What is the maximum length available for Monel tubes?

TSM Technology offers Monel tubes with a maximum length of 15000 mm.

Are customization and processing options available for Monel tubes?

Yes, TSM Technology supports customization and processing of Monel tubes to meet specific project requirements.

What surface treatments are available for Monel tubes?

TSM Technology offers surface treatments such as sandblasting and anodising for Monel tubes.

What certifications are provided with Monel tubes?

Material Test Certificates (MTC) and SGS test reports are available for TSM Technology's Monel tubes.

Can I get a free sample of Monel tubes?

Yes, TSM Technology provides free samples of Monel tubes upon request.

Choose TSM TECHNOLOGY for Premium Monel Tubes

TSM Technology, a leading Monel tube manufacturer and supplier, offers superior quality Monel 400 (UNS N04400) tubes that meet ASTM B163, ASME SB163, and EN 10095 standards. With three state-of-the-art factories, eight production lines, and over 100 specialised machines, we ensure unparalleled precision and quality in every tube we produce. Our Monel tubes, available in OD ranges of 6.0-114 mm and wall thicknesses of 0.5-15 mm, are backed by rigorous testing and certifications. For inquiries or to request a free sample, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2022). "Marine Engineering Materials: Advances in Corrosion-Resistant Alloys." Journal of Naval Architecture and Marine Engineering, 45(3), 278-295.

Brown, A.L. & Johnson, K.M. (2021). "Comparative Study of Nickel-Copper Alloys in Offshore Applications." Corrosion Science, 163, 108761.

International Nickel Study Group. (2023). "Annual Report on Nickel Alloys in Marine Environments."

Lee, S.H., et al. (2020). "Long-term Performance of Monel Tubes in Seawater Heat Exchangers." Materials and Corrosion, 71(9), 1452-1465.

American Society for Testing and Materials. (2021). "ASTM B163-21: Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes."

Wilson, R.D. (2023). "Advancements in Manufacturing Techniques for High-Performance Marine Alloys." Journal of Materials Processing Technology, 305, 117534.

Learn about our latest products and discounts through SMS or email