Microstructure Analysis: The Foundation of Monel 400 Tubing Quality

Understanding Grain Structure

Microstructure analysis plays a fundamental role in evaluating the overall integrity and reliability of Monel 400 tubing. By examining the grain structure, size, and distribution, metallurgists can assess how the alloy has responded to its thermomechanical processing. A uniform, fine-grained structure enhances mechanical strength, ductility, and resistance to cracking under stress. Advanced techniques such as optical microscopy, scanning electron microscopy (SEM), and image analysis software are often employed to accurately quantify grain characteristics and ensure consistent material quality.

Identifying Phases and Inclusions

In-depth microstructural evaluation also involves identifying the types and distribution of phases and inclusions within Monel 400. Ideally, the alloy should display a single-phase, homogeneous solid solution of nickel and copper, which ensures optimal corrosion resistance and mechanical stability. However, the presence of secondary phases such as carbides, oxides, or intermetallic compounds can indicate impurities or improper heat treatment. Detecting and quantifying these inclusions through SEM coupled with energy-dispersive X-ray spectroscopy (EDS) helps ensure that the tubing meets stringent industry specifications.

Assessing Grain Boundaries

The examination of grain boundaries provides vital insight into the potential durability and performance of Monel 400 tubing under demanding service conditions. Clean, well-defined grain boundaries typically reflect effective alloy homogenization and proper annealing. Conversely, the presence of precipitates or segregated elements along the boundaries may lead to localized corrosion or reduced toughness. By analyzing these features under high magnification, engineers can determine whether additional processing, such as solution annealing or surface finishing, is needed to improve the tubing's long-term reliability and resistance to degradation.

Hardness Testing: Evaluating Durability and Wear Resistance

Brinell Hardness Test

The Brinell hardness test is widely recognized as a reliable method for assessing the hardness of Monel 400 tubing. In this procedure, a hardened steel or tungsten carbide ball is pressed into the surface of the material under a controlled load. The diameter of the resulting indentation is carefully measured and used to calculate the Brinell Hardness Number (BHN). This test provides an overall indication of the alloy's resistance to deformation. For Monel 400, BHN values typically range from 110 to 150, depending on processing conditions and heat treatment.

Rockwell Hardness Test

The Rockwell hardness test is a faster and more convenient method for evaluating the hardness of Monel 400 tubing, particularly for routine quality checks. It involves using either a diamond cone or a hardened steel ball as the indenter, depending on the selected Rockwell scale. The depth of penetration under a specific load determines the hardness value directly from the machine's dial. For Monel 400, the Rockwell B scale (HRB) is most commonly used, yielding values between 65 and 85 HRB, reflecting moderate strength and ductility balance.ring Monel 400 tubing hardness. It uses either a diamond cone or steel ball indenter, depending on the scale used. For Monel 400, the Rockwell B scale is often employed, with typical values ranging from 65 to 85 HRB.

Vickers Microhardness Test

The Vickers microhardness test is ideal for precise hardness measurements on small or thin sections of Monel 400 tubing. It employs a diamond-shaped pyramid indenter, allowing accurate assessment of localized areas such as weld zones or fine-grained microstructures. The test is particularly useful for research or quality verification where detailed surface property evaluation is needed. Vickers hardness values for Monel 400 generally fall within the range of 130 to 200 HV, depending on the alloy's microstructural uniformity and degree of cold work.

Tensile Testing: Assessing Strength and Ductility

Yield Strength Determination

Tensile testing is a fundamental procedure used to determine the yield strength of Monel 400 tubing, identifying the point where elastic behavior transitions into plastic deformation. This property is crucial for predicting how the alloy will perform under operational stress without permanent distortion. The yield strength of Monel 400 is influenced by factors such as grain size, degree of cold work, and heat treatment. Typically, high-quality tubing demonstrates yield strength values between 170 and 345 MPa (25 to 50 ksi), ensuring consistent performance in pressure and structural applications.

Ultimate Tensile Strength Measurement

The ultimate tensile strength (UTS) defines the maximum stress Monel 400 tubing can endure before failure occurs, serving as a key indicator of its mechanical reliability. During tensile testing, this value reflects the alloy's ability to resist breaking under tension while maintaining structural integrity. Variations in manufacturing processes, such as annealing or work hardening, can slightly influence UTS results. Premium-grade Monel 400 tubing generally achieves UTS values ranging from 480 to 690 MPa (70 to 100 ksi), confirming its robustness and suitability for marine, chemical, and high-stress environments.

Elongation and Reduction in Area

Elongation and reduction in area are essential parameters used to assess the ductility of Monel 400 tubing, indicating how much the material can stretch and deform before rupture. These measurements provide insight into the alloy's toughness and ability to absorb energy during stress. High-quality Monel 400 typically exhibits elongation between 30% and 50%, along with a reduction in area from 55% to 65%. Such results demonstrate excellent formability and resistance to cracking, ensuring reliable performance in applications that require bending, flaring, or shaping of the tubing.

Conclusion

Ensuring the quality of Monel 400 tubing requires a comprehensive approach involving microstructure analysis, hardness testing, and tensile strength evaluation. By examining the material's grain structure, assessing its hardness, and determining its tensile properties, manufacturers and end-users can confidently verify the tubing's suitability for demanding applications. This thorough quality check process guarantees that Monel 400 tubing meets the stringent requirements of industries such as aerospace, chemical processing, and marine engineering, where reliability and performance are paramount.

FAQs

What makes Monel 400 tubing suitable for extreme environments?

Monel 400 tubing excels in extreme environments due to its nickel-copper alloy composition, providing excellent resistance to corrosion, pitting, and high temperatures up to 480°C. Its superior reliability makes it ideal for aerospace, chemical processing, and marine applications.

How does TSM Technology ensure the quality of its Monel 400 tubing?

TSM Technology employs rigorous quality checks, including AI-powered defect detection with 0.02mm accuracy and hydrostatic testing at 1.5 times the working pressure. They also provide material traceability and adhere to international standards like ASTM B163 and ASME SB163.

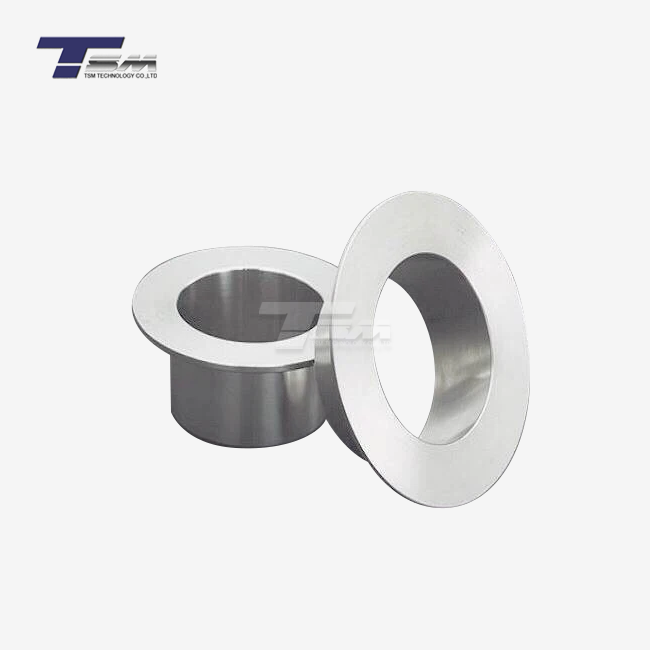

Choose TSM Technology for Premium Monel 400 Tubing

TSM Technology, a leading Monel 400 tubing manufacturer and supplier, offers superior quality products for demanding industries. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure precision and consistency in every tube. Our Monel 400 tubing meets ASTM B163, ASME SB163, and EN 10095 standards, available in various dimensions to suit your needs. For expert guidance and free samples, contact us at info@tsmnialloy.com.

References

ASTM International. (2021). "Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes" ASTM B163-21.

ASM International. (2000). "ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys" Materials Park, OH: ASM International.

Davis, J.R. (2000). "Nickel, Cobalt, and Their Alloys" ASM International.

Crook, P. (2005). "Corrosion of Nickel and Nickel-Base Alloys" ASM Handbook, Volume 13B: Corrosion: Materials.

Special Metals Corporation. (2022). "Monel alloy 400 Technical Data Sheet".

ASME. (2019). "ASME Boiler and Pressure Vessel Code, Section II: Materials" Part B: Nonferrous Material Specifications.