Composition and Properties of Nickel 201 Sheet

Chemical Makeup and Purity Levels

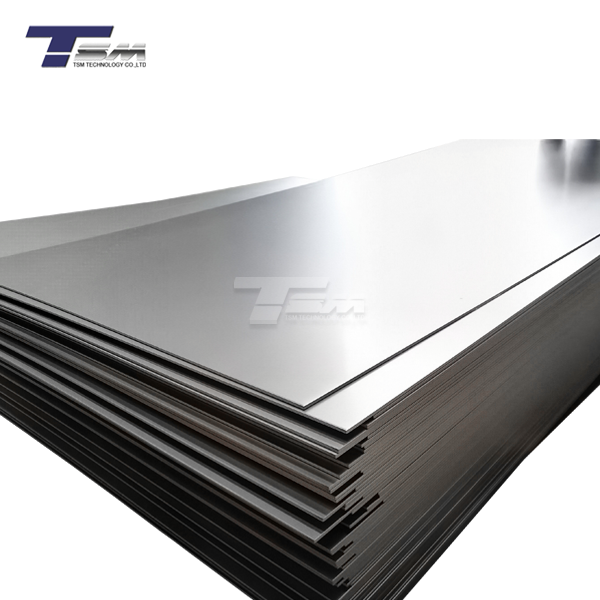

Nickel 201 sheet boasts an impressive purity level, typically containing over 99% nickel. This high nickel content contributes significantly to its desirable properties. The remaining composition usually includes trace amounts of elements such as carbon, manganese, iron, sulfur, and copper. These minimal additions are carefully controlled to enhance specific characteristics without compromising the alloy's overall performance.

The purity of Nickel 201 plate is paramount to its functionality. Unlike some other nickel alloys, Nickel 201 has a lower carbon content, which improves its resistance to intergranular corrosion. This feature is particularly valuable in applications where the material might be exposed to high temperatures for extended periods.

Mechanical Characteristics

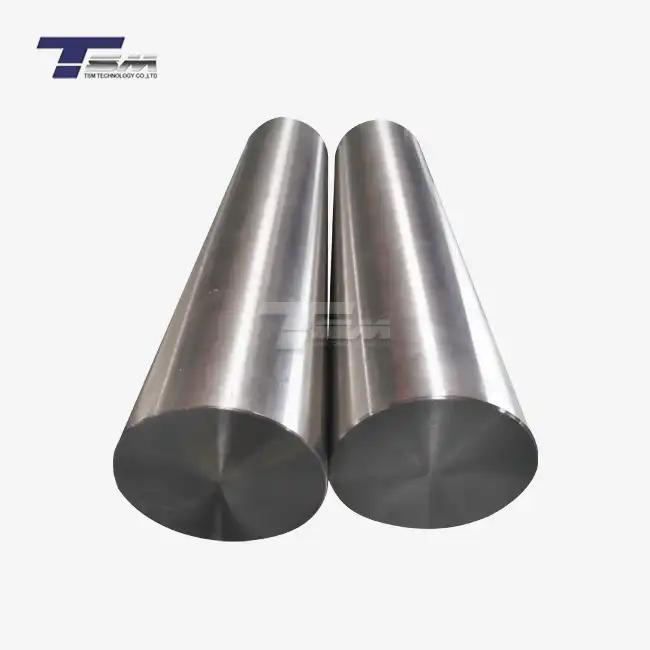

Nickel 201 sheet exhibits remarkable mechanical properties that make it suitable for a wide range of industrial uses. It possesses excellent ductility, allowing it to be formed into complex shapes without cracking or breaking. This malleability is complemented by its high tensile strength, which ensures that components made from Nickel 201 can withstand significant stresses.

Moreover, the material maintains its structural integrity across a broad temperature spectrum. From cryogenic applications to high-temperature environments, Nickel 201 plate demonstrates consistent performance. Its low yield strength at elevated temperatures allows for stress relief, reducing the risk of warping or distortion in demanding thermal conditions.

Thermal and Electrical Conductivity

One of the standout features of Nickel 201 sheet is its exceptional thermal conductivity. This property makes it an ideal choice for heat exchangers and other applications where efficient heat transfer is crucial. The material's ability to distribute heat evenly helps prevent localized hot spots that could lead to premature failure or reduced efficiency in industrial equipment.

In addition to its thermal properties, Nickel 201 plate also exhibits good electrical conductivity. While not as conductive as copper, it offers a balance of electrical performance and corrosion resistance that makes it valuable in certain electrical components, particularly those exposed to harsh environments.

Applications and Industries Utilizing Nickel 201 Sheet

Chemical Processing Equipment

The chemical processing industry heavily relies on Nickel 201 sheet for various components. Its exceptional resistance to corrosion, especially in caustic environments, makes it ideal for reactor vessels, heat exchangers, and piping systems. In these applications, the material's ability to withstand aggressive chemicals while maintaining its structural integrity is paramount.

Nickel 201 plate is particularly valuable in the production of caustic soda and other alkaline compounds. Its resistance to stress corrosion cracking in hot caustic solutions ensures long-term reliability and reduces the need for frequent equipment replacement or maintenance. This translates to improved operational efficiency and reduced downtime for chemical plants.

Aerospace and Defense Industries

The aerospace sector utilizes Nickel 201 sheet in various critical components. Its high-temperature strength and resistance to oxidation make it suitable for parts in jet engines and rocket propulsion systems. The material's ability to maintain its properties in extreme conditions contributes to the safety and reliability of aerospace applications.

In defense applications, Nickel 201 plate finds use in naval equipment, particularly in systems exposed to seawater. Its corrosion resistance in marine environments helps extend the lifespan of critical components, reducing maintenance costs and improving the readiness of naval assets.

Food Processing and Pharmaceutical Industries

The food and pharmaceutical industries benefit from the hygienic properties of Nickel 201 sheet. Its smooth surface finish and resistance to bacterial growth make it an excellent choice for processing equipment, storage tanks, and piping systems. The material's ability to withstand cleaning agents and sterilization processes without degradation ensures that it meets stringent hygiene standards.

In pharmaceutical manufacturing, Nickel 201 plate is often used in reactors and vessels for producing high-purity drugs. Its resistance to a wide range of chemicals and its non-contaminating nature help maintain the integrity of pharmaceutical products throughout the production process.

Manufacturing and Fabrication of Nickel 201 Sheet

Production Processes

The manufacturing of Nickel 201 sheet begins with the careful selection and melting of high-purity nickel. Advanced melting techniques, such as vacuum induction melting or electroslag remelting, are employed to ensure the material's purity and homogeneity. These processes help remove impurities and control the alloy's composition with precision.

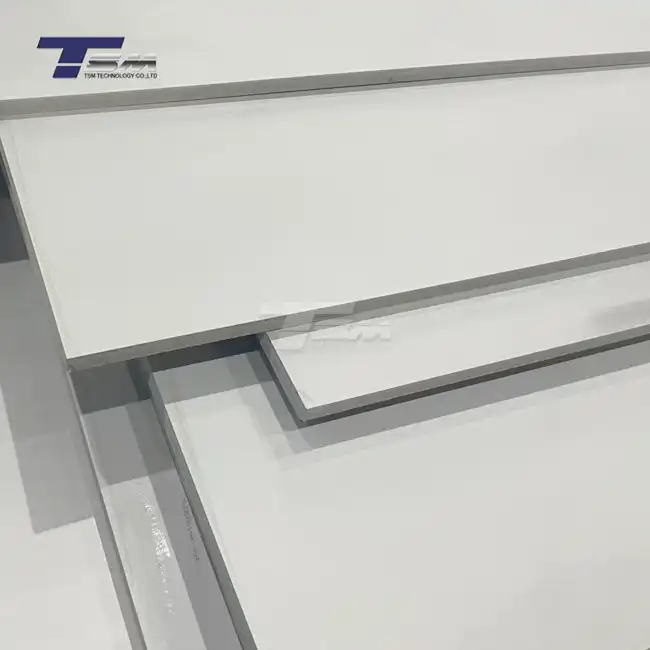

Once melted, the nickel is cast into ingots or continuous cast slabs. These are then subjected to a series of hot and cold rolling operations to achieve the desired thickness and surface finish of the Nickel 201 plate. Throughout this process, strict quality control measures are implemented to maintain the material's properties and dimensional accuracy.

Forming and Shaping Techniques

Nickel 201 sheet's excellent formability allows for a variety of shaping techniques. It can be easily cold-formed using conventional methods such as bending, drawing, and spinning. For more complex shapes, hot forming may be employed, taking advantage of the material's increased ductility at elevated temperatures.

Advanced forming techniques, including hydroforming and superplastic forming, can be used to create intricate components from Nickel 201 plate. These methods allow for the production of parts with tight tolerances and complex geometries, expanding the range of possible applications for this versatile material.

Welding and Joining Methods

Nickel 201 sheet can be welded using various techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. The material's good weldability ensures strong, reliable joints that maintain the corrosion resistance and mechanical properties of the base metal.

When welding Nickel 201 plate, it's crucial to use appropriate filler metals and follow proper procedures to avoid contamination and maintain the alloy's integrity. Post-weld heat treatment may be necessary in some cases to relieve stresses and optimize the joint's performance.

Conclusion

Nickel 201 sheet stands as a cornerstone material in numerous industrial applications, offering a unique combination of corrosion resistance, thermal properties, and formability. Its high purity and carefully controlled composition make it an invaluable asset in chemical processing, aerospace, food production, and pharmaceutical manufacturing. As industries continue to push the boundaries of material performance, Nickel 201 plate remains at the forefront, enabling innovations and ensuring the reliability of critical components in challenging environments. The versatility and durability of this remarkable alloy underscore its essential role in driving technological advancements and industrial efficiency across various sectors.

Contact Us

For more information about Nickel 201 sheet and other superior alloy products, please don't hesitate to contact us at info@tsm-technology.com. Our team of experts is ready to assist you in finding the perfect material solution for your specific needs.