- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the ASTM standard for Inconel 718 Tubes?

If you're searching for the ASTM standard for Inconel 718 tubes, the answer is straightforward: the applicable standard is ASTM B163 for seamless nickel alloy tubes and ASTM B516 for welded nickel alloy tubes. These standards outline the rigorous specifications for Inconel 718, ensuring its suitability for high-performance applications in industries like aerospace, oil and gas, and chemical processing. At TSM Technology Co., Ltd., we adhere to these exacting standards, delivering superior nickel alloy products globally. Curious about how these standards impact the quality and performance of Inconel 718 tubes? Let's dive deeper into the world of this remarkable material.

Understanding Inconel 718 and Its ASTM Standards

What Makes Inconel 718 a Superior Alloy?

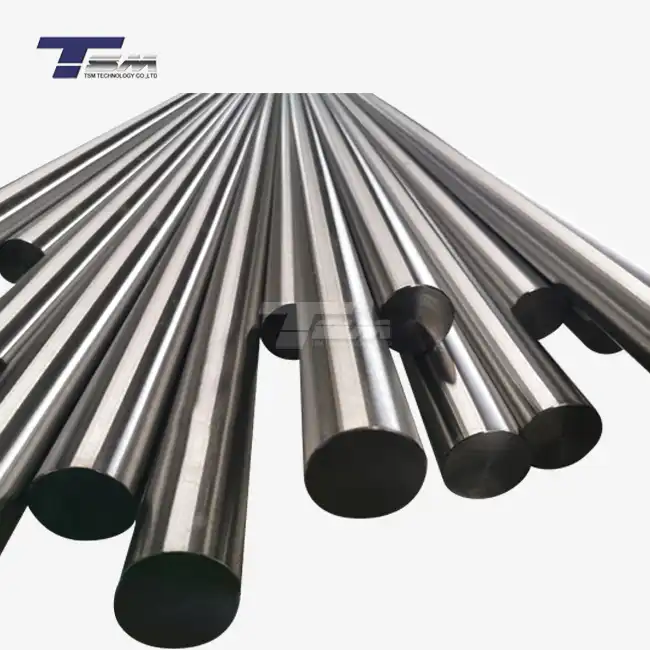

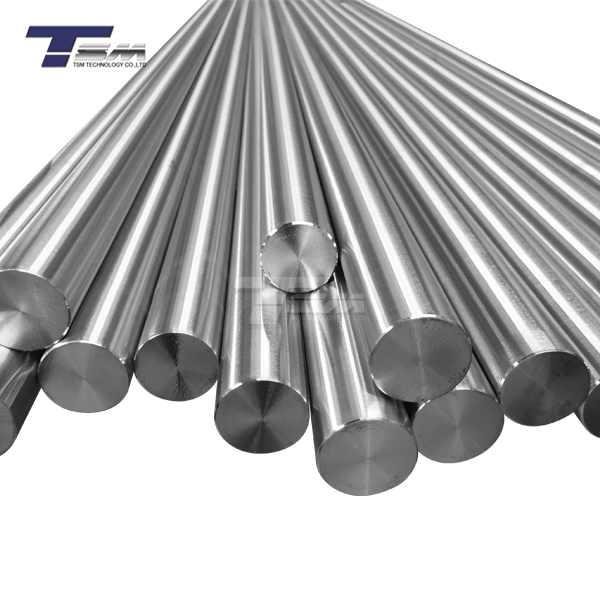

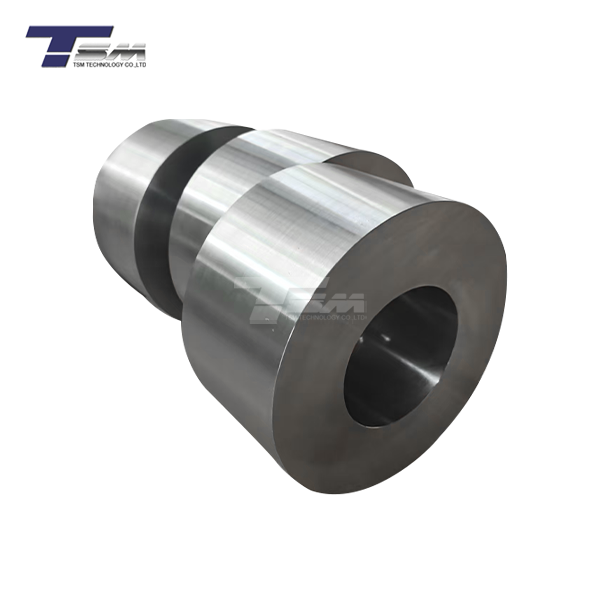

Inconel 718 is a nickel-chromium alloy renowned for its exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. This superalloy is a go-to material in industries requiring components that endure harsh environments, such as jet engines, gas turbines, and deep-sea drilling equipment. Its unique composition, which includes niobium, molybdenum, and titanium, enhances its mechanical properties, making it ideal for both seamless and welded tubing applications. At TSM Technology Co., Ltd., we specialize in supplying Inconel 718 tubes and pipes that meet the highest industry benchmarks, ensuring reliability in even the most demanding conditions.

The Role of ASTM Standards in Quality Assurance

ASTM standards are globally recognized benchmarks that define the properties, manufacturing processes, and testing methods for materials like Inconel 718. For Inconel 718 tubes, ASTM B163 governs seamless tubes, while ASTM B516 applies to welded tubes. These standards specify critical parameters such as chemical composition, mechanical strength, and dimensional tolerances, ensuring consistency and safety. By adhering to these protocols, manufacturers like TSM Technology Co., Ltd. guarantee that every Inconel 718 pipe meets stringent quality requirements, providing peace of mind to engineers and procurement specialists worldwide.

Why Compliance with ASTM Standards Matters?

Compliance with ASTM standards is not just a regulatory formality; it's a cornerstone of performance and safety. Non-compliant materials risk premature failure, costly downtime, or even catastrophic accidents in high-stakes applications. For industries relying on Inconel 718 pipes, such as aerospace and petrochemical, adherence to ASTM B163 and B516 ensures that the tubing can endure extreme pressures, temperatures, and corrosive environments. At TSM, our rigorous quality control system, backed by professional inspectors, ensures that every product surpasses these standards, reinforcing our reputation as a trusted global supplier of superior nickel alloys.

Applications and Benefits of Inconel 718 Tubes

High-Performance Applications Across Industries

Inconel 718 tubes are indispensable in sectors where failure is not an option. In aerospace, they are used in engine components and exhaust systems, where they endure temperatures exceeding 1,200°F (649°C). In the oil and gas sector, Inconel 718 pipes are deployed in downhole tools and subsea equipment, resisting corrosion from sour gas and seawater. Chemical processing plants also rely on this alloy for heat exchangers and reactor vessels, thanks to its resistance to oxidation and scaling. TSM Technology Co., Ltd. caters to these precision engineering needs, offering tailored solutions for machine shops and manufacturers worldwide.

Key Benefits of Using Inconel 718 Tubes

The allure of Inconel 718 lies in its multifaceted advantages. Its high tensile strength and fatigue resistance make it ideal for dynamic applications, while its corrosion resistance ensures longevity in aggressive environments. Additionally, Inconel 718 tubes maintain their integrity across a wide temperature range, from cryogenic lows to blistering highs. This versatility reduces the need for frequent replacements, lowering operational costs. At TSM, we enhance these benefits by offering Inconel 718 pipes and tubes in various dimensions and forms, all rigorously inspected to meet ASTM standards, ensuring optimal performance for your specific application.

How Inconel 718 Compares to Other Nickel Alloys?

While other nickel alloys like Monel, Incoloy, and Hastelloy offer impressive properties, Inconel 718 stands out for its unparalleled strength-to-weight ratio and high-temperature stability. Unlike Monel, which excels in marine environments, Inconel 718 is better suited for extreme thermal and mechanical stress. Compared to Hastelloy, which prioritizes corrosion resistance, Inconel 718 offers superior creep resistance, making it ideal for prolonged high-temperature exposure. TSM Technology Co., Ltd. provides a comprehensive range of these superior alloys, allowing customers to select the perfect material for their unique challenges, backed by our expertise and innovation.

Choosing the Right Inconel 718 Tubes for Your Project

Factors to Consider When Selecting Inconel 718 Tubes

Selecting the right Inconel 718 tubes requires careful consideration of several factors. Application environment is paramount - will the tubing face extreme temperatures, corrosive substances, or high pressures? Seamless Inconel 718 tubes, governed by ASTM B163, are preferred for applications requiring maximum strength and leak resistance, while welded Inconel 718 pipes, under ASTM B516, are cost-effective for less critical uses. Dimensional specifications, such as outer diameter, wall thickness, and length, also play a crucial role. At TSM Technology Co., Ltd., our team assists customers in navigating these choices, ensuring the selected product aligns perfectly with project demands.

The Importance of Quality Control in Manufacturing

Quality control is the bedrock of reliable Inconel 718 tube. At TSM, our manufacturing process incorporates advanced techniques and meticulous inspections to ensure compliance with ASTM standards. Each Inconel 718 tube undergoes rigorous testing, including hydrostatic, ultrasonic, and chemical analysis, to verify its integrity. Our professional inspectors scrutinize every batch, ensuring that defects, inclusions, or deviations are eliminated. This stringent approach, honed over 14 years of international trading, positions TSM as a leader in the superior nickel alloy market, delivering products that engineers and machine shops can trust for precision and durability.

Partnering with a Trusted Supplier Like TSM Technology

Choosing a supplier is as critical as selecting the material itself. A reputable supplier ensures consistent quality, timely delivery, and technical support. Since our inception in 2011 in Hong Kong, TSM Technology Co., Ltd. has grown into a global leader in superior nickel alloys, including Inconel 718 tubes and pipes. Our commitment to innovation drives us to develop new alloys and enhance existing ones, meeting the evolving needs of the precision engineering industry. With a robust quality control system and a customer-centric approach, TSM is your ideal partner for sourcing high-performance materials that elevate your projects.

Conclusion

Inconel 718 tubes, governed by ASTM B163 for seamless and ASTM B516 for welded forms, are vital for industries demanding strength, corrosion resistance, and thermal stability. Understanding these standards, their applications, and the benefits of this superalloy empowers you to make informed decisions for your projects. TSM Technology Co., Ltd. stands ready to support you with top-tier Inconel 718 products, backed by rigorous quality control and global expertise. Elevate your engineering solutions with our superior nickel alloys.

Contact Us

For more information about our high-quality Inconel 718 tubes and other superior alloy products, please contact us at info@tsm-technology.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

ASTM International, "ASTM B163 - Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes," ASTM Standards, Volume 02.04.

ASTM International, "ASTM B516 - Standard Specification for Welded Nickel-Chromium-Iron Alloy Tubes," ASTM Standards, Volume 02.04.

Special Metals Corporation, "Inconel Alloy 718 - Technical Data Sheet," Materials Engineering Series.

Nickel Institute, "High-Performance Nickel Alloys for Extreme Environments," Technical Publication No. 12-034.

American Society of Mechanical Engineers, "ASME Boiler and Pressure Vessel Code, Section II - Materials," Part D - Properties.

International Organization for Standardization, "ISO 6207 - Seamless Nickel and Nickel Alloy Tube," ISO Standards Catalogue.

Learn about our latest products and discounts through SMS or email