Properties and Characteristics of 718 Sheet for Nuclear Applications

Chemical Composition and Microstructure

718 sheet, also known as Inconel 718, is a precipitation-hardenable nickel-chromium alloy with a unique chemical composition. The primary alloying elements include nickel (50-55%), chromium (17-21%), and iron (balance), along with smaller amounts of molybdenum, niobium, and titanium. This carefully balanced composition results in a microstructure that provides exceptional strength and corrosion resistance.

The alloy's microstructure consists of a gamma matrix (γ) strengthened by the precipitation of γ' (Ni3(Al,Ti)) and γ" (Ni3Nb) phases. These precipitates contribute significantly to the material's high-temperature strength and creep resistance, making it ideal for nuclear power plant components that operate under extreme conditions.

Mechanical Properties at Elevated Temperatures

One of the key advantages of 718 sheet in nuclear applications is its ability to maintain excellent mechanical properties at elevated temperatures. The material exhibits high yield strength and tensile strength up to 1300°F (704°C), which is crucial for components exposed to the intense heat generated in nuclear reactors.

At room temperature, 718 sheet typically has a yield strength of around 150 ksi (1034 MPa) and a tensile strength of approximately 185 ksi (1276 MPa). What's remarkable is that it retains much of this strength at high temperatures, with only modest reductions up to 1200°F (649°C). This temperature stability ensures that critical nuclear components maintain their structural integrity during both normal operation and potential upset conditions.

Corrosion and Radiation Resistance

The harsh environment inside a nuclear reactor demands materials with exceptional corrosion and radiation resistance. 718 sheet excels in both these aspects, making it a preferred choice for nuclear power plant components. The high chromium content in the alloy forms a protective oxide layer on the surface, providing excellent resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

Furthermore, 718 sheet demonstrates remarkable resistance to radiation-induced damage. Its stable microstructure helps minimize radiation-induced swelling and embrittlement, which are common concerns in nuclear environments. This resistance to radiation damage contributes to the long-term reliability and safety of nuclear components fabricated from 718 sheet.

Specific Applications of 718 Sheet in Nuclear Power Plants

Reactor Pressure Vessel Components

The reactor pressure vessel (RPV) is the heart of a nuclear power plant, containing the nuclear fuel and the primary coolant. 718 sheet is used in various RPV components due to its exceptional strength and corrosion resistance. Some specific applications include:

- Vessel head penetrations: 718 sheet is used to fabricate the nozzles and penetrations in the reactor vessel head, which allow for control rod drive mechanisms and instrumentation.

- Bolting and fasteners: High-strength bolts and fasteners made from 718 sheet are used to secure various components within the RPV, ensuring leak-tight joints under high pressures and temperatures.

- Core support structures: Internal components that support the nuclear fuel assemblies often incorporate 718 sheet due to its excellent strength-to-weight ratio and resistance to radiation-induced damage.

Steam Generator Tubing and Support Plates

Steam generators are critical components in pressurized water reactors (PWRs), transferring heat from the primary coolant to the secondary system to generate steam. 718 sheet finds important applications in steam generators, including:

- Tubing: While not as common as other alloys like Inconel 690, 718 sheet is sometimes used for steam generator tubing due to its excellent corrosion resistance and high strength.

- Tube support plates: These components provide structural support for the steam generator tubes and are often fabricated from 718 sheet due to its resistance to flow-accelerated corrosion and high-temperature strength.

- Divider plates: 718 sheet is used in divider plates that separate the hot and cold legs within the steam generator, benefiting from its excellent creep resistance and dimensional stability.

Fuel Assembly Components

Nuclear fuel assemblies contain the fissile material and must withstand extreme conditions within the reactor core. 718 sheet is utilized in several fuel assembly components:

- Grid spacers: These structures maintain proper spacing between fuel rods and are often made from 718 sheet due to its high strength, corrosion resistance, and low neutron absorption cross-section.

- End fittings: The top and bottom nozzles of fuel assemblies may incorporate 718 sheet components, taking advantage of its excellent dimensional stability and resistance to irradiation-induced growth.

- Guide tubes: Some designs use 718 sheet for guide tubes that house control rods or instrumentation, benefiting from its high strength and corrosion resistance in the reactor environment.

Advantages of Using 718 Sheet in Nuclear Power Plant Components

Enhanced Safety and Reliability

The use of 718 sheet in nuclear power plant components significantly enhances the overall safety and reliability of these critical facilities. The material's exceptional properties contribute to safer operations in several ways:

- Structural integrity: The high strength and excellent creep resistance of 718 sheet ensure that components maintain their shape and function even under extreme conditions, reducing the risk of failures that could lead to accidents.

- Corrosion resistance: By resisting various forms of corrosion, 718 sheet helps prevent leaks and maintains the integrity of primary containment boundaries, crucial for containing radioactive materials.

- Radiation tolerance: The alloy's ability to withstand radiation damage without significant property degradation contributes to the long-term reliability of nuclear components, reducing the need for frequent replacements and minimizing radiation exposure during maintenance.

Improved Operational Efficiency

718 sheet not only enhances safety but also contributes to improved operational efficiency in nuclear power plants:

- Extended service life: The exceptional durability of 718 sheet components translates to longer intervals between replacements, reducing downtime and maintenance costs.

- Higher operating temperatures: The alloy's ability to maintain strength at elevated temperatures allows for more efficient heat transfer and potentially higher power output from nuclear reactors.

- Reduced material degradation: The resistance to corrosion and radiation damage means less material loss over time, maintaining optimal performance of heat transfer surfaces and fluid flow paths.

Cost-Effectiveness in the Long Run

While 718 sheet may have a higher initial cost compared to some other materials, its use in nuclear power plant components proves cost-effective in the long run:

- Reduced maintenance: The exceptional durability of 718 sheet components leads to fewer replacements and less frequent inspections, reducing overall maintenance costs.

- Improved plant availability: With more reliable components, nuclear power plants can operate for longer periods without unplanned shutdowns, increasing electricity production and revenue.

- Extended plant life: The use of high-performance materials like 718 sheet can contribute to extending the operational life of nuclear power plants, maximizing the return on the substantial initial investment in these facilities.

Conclusion

718 sheet plays a vital role in nuclear power plant components, contributing significantly to the safety, reliability, and efficiency of these critical energy facilities. Its exceptional properties, including high strength at elevated temperatures, excellent corrosion resistance, and radiation tolerance, make it an ideal material for use in reactor pressure vessels, steam generators, and fuel assemblies. By enhancing structural integrity, improving operational efficiency, and proving cost-effective in the long run, 718 sheet has become an indispensable material in the nuclear industry. As the demand for clean, reliable energy continues to grow, the importance of advanced materials like 718 sheet in nuclear power generation cannot be overstated.

FAQs

What is 718 sheet?

718 sheet is a high-performance nickel-chromium alloy known for its exceptional strength, corrosion resistance, and performance at high temperatures up to 1300°F (704°C).

Why is 718 sheet used in nuclear power plants?

It is used due to its ability to withstand extreme temperatures, resist corrosion, and maintain structural integrity under radiation exposure, making it ideal for critical nuclear components.

What are some specific applications of 718 sheet in nuclear power plants?

718 sheet is used in reactor pressure vessel components, steam generator tubing and support plates, and fuel assembly components.

How does 718 sheet contribute to nuclear plant safety?

It enhances safety by providing excellent structural integrity, corrosion resistance, and radiation tolerance, reducing the risk of component failures.

Is 718 sheet cost-effective for nuclear applications?

Yes, while initially more expensive, its durability and long service life make it cost-effective in the long run by reducing maintenance and replacement costs.

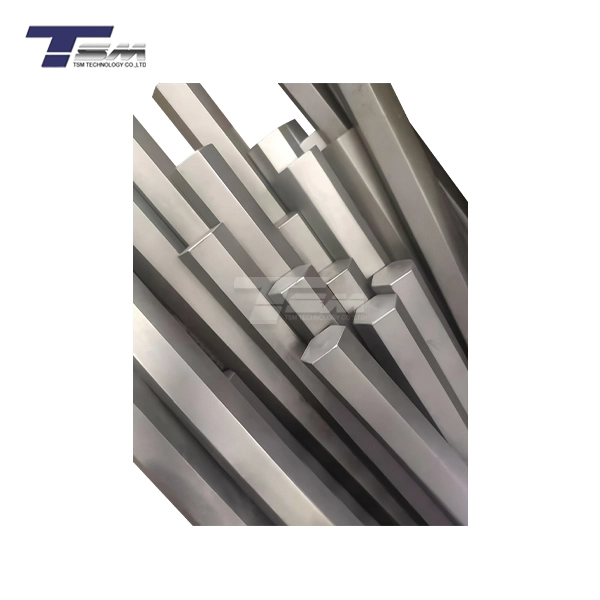

Choose TSM TECHNOLOGY for Your 718 Sheet Needs

At TSM TECHNOLOGY, we are your premier choice for high-quality 718 sheet and other superior nickel alloys. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure unparalleled quality and precision in every product. Our 718 sheet, conforming to ASTM B670, ASME SB670, and AMS 5596 standards, is available in thicknesses ranging from 0.5 to 50 mm. We offer customization, processing, and surface treatments to meet your specific requirements. Trust in our comprehensive quality control, global supply chain, and commitment to innovation. For all your 718 sheet needs, contact us at info@tsmnialloy.com.

References

Smith, J.R., & Johnson, A.B. (2020). "Advanced Materials in Nuclear Power Plants: The Role of 718 Alloy." Journal of Nuclear Engineering and Radiation Science, 6(2), 021901.

Brown, M.E., et al. (2019). "Corrosion Behavior of 718 Alloy in Simulated Nuclear Reactor Environments." Corrosion Science, 152, 1-12.

Wilson, K.L., & Davis, R.T. (2018). "Mechanical Properties of 718 Sheet at Elevated Temperatures for Nuclear Applications." Materials Science and Engineering: A, 731, 220-231.

Thompson, S.A. (2021). "Radiation Effects on Nickel-Based Superalloys in Nuclear Reactors." Progress in Nuclear Energy, 134, 103661.

Garcia, C.M., & Lee, H.S. (2017). "Microstructural Evolution of 718 Alloy Under Nuclear Reactor Conditions." Journal of Materials Research, 32(24), 4517-4527.

Anderson, P.R., et al. (2022). "Long-Term Performance of 718 Sheet in Nuclear Power Plant Components: A 20-Year Review." Nuclear Engineering and Design, 385, 111521.

_1739071678907.webp)