- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Cold Working Improves Monel 400 Strength and Resistance?

Cold working significantly enhances the strength and resistance of Monel 400, a versatile nickel-copper alloy. This process involves deforming the metal at room temperature, which induces strain hardening. As a result, the alloy's yield strength, tensile strength, and hardness increase substantially. Simultaneously, cold working refines the grain structure, improving corrosion resistance and fatigue life. For Monel 400 tubes and pipes, this translates to superior performance in demanding applications, from marine environments to chemical processing. The combination of increased strength and enhanced resistance makes cold-worked Monel 400 an ideal choice for critical components in aerospace, oil and gas, and other industries requiring high-performance materials.

The Science Behind Cold Working Monel 400

Understanding the Microstructure Changes

Cold working Monel 400 induces significant changes at the microstructural level. As the material undergoes plastic deformation, dislocations within the crystal lattice multiply and interact. This process leads to a higher dislocation density, which impedes further dislocation movement. The result is a finer grain structure with increased grain boundaries, contributing to the alloy's enhanced strength and resistance properties.

Strain Hardening Mechanism

The strain hardening mechanism is central to the improvements observed in cold-worked Monel 400. As the material is deformed, the interaction between dislocations creates obstacles that resist further deformation. This phenomenon increases the yield strength and ultimate tensile strength of the alloy. For Monel tubing applications, this translates to higher pressure ratings and improved resistance to mechanical stresses.

Impact on Corrosion Resistance

Interestingly, cold working can also positively impact the corrosion resistance of Monel 400 pipes. The refined grain structure resulting from cold working creates a more uniform surface, reducing potential sites for corrosion initiation. Additionally, the increased density of grain boundaries can act as barriers to corrosion propagation, further enhancing the alloy's already impressive resistance to various corrosive environments.

Quantifying the Improvements in Monel 400 Properties

Mechanical Property Enhancements

Cold working can dramatically improve the mechanical properties of Monel 400. Yield strength can increase by up to 200%, while tensile strength may see improvements of 50% or more. Hardness values also rise significantly, often doubling from the annealed state. These enhancements make cold-worked Monel 400 tubes ideal for applications requiring high strength-to-weight ratios, such as in aerospace components or high-pressure piping systems.

Fatigue Life and Wear Resistance

The fatigue life of cold-worked Monel 400 is substantially improved due to the increased strength and refined microstructure. This is particularly beneficial for Monel 400 pipes subjected to cyclic loading conditions. Wear resistance also sees a marked improvement, making cold-worked Monel tubing an excellent choice for applications involving abrasive environments or frequent material flow.

Corrosion Performance Metrics

While Monel 400 is already known for its excellent corrosion resistance, cold working can further enhance this property. Studies have shown that cold-worked Monel 400 can exhibit up to 20% improvement in corrosion rates in certain environments, such as seawater or acidic solutions. This enhancement is particularly valuable for Monel 400 pipes used in marine applications or chemical processing industries.

Applications Benefiting from Cold-Worked Monel 400

Marine and Offshore Industries

In marine and offshore environments, cold-worked Monel 400 tubes demonstrate exceptional performance due to their enhanced strength and superior corrosion resistance. They are particularly suitable for seawater handling systems, desalination plants, and offshore oil and gas platforms, where both mechanical durability and chemical resistance are essential. The cold-working process improves fatigue life, ensuring that components can withstand constant wave action, pressure fluctuations, and prolonged exposure to corrosive seawater. This combination of properties guarantees long-lasting, reliable operation in some of the most challenging marine conditions.

Chemical Processing Equipment

Cold-worked Monel 400 pipes provide significant advantages in chemical processing applications. Their increased strength allows for thinner-walled tubing, reducing material usage and overall costs without compromising structural integrity. The improved corrosion resistance is vital for handling aggressive chemicals, acids, and alkaline solutions, minimizing the risk of chemical attack and material degradation. As a result, equipment longevity is enhanced, maintenance requirements are reduced, and operational efficiency is improved. Cold-worked Monel 400 ensures safe, reliable, and cost-effective performance in demanding industrial chemical processing environments.

Aerospace and Defense Applications

In aerospace and defense applications, cold-worked Monel 400 tubing is valued for its high strength-to-weight ratio, which supports weight reduction without sacrificing performance. It is commonly used in fuel systems, hydraulic lines, and critical structural components, where reliability and longevity under repeated stress are essential. The cold-working process enhances fatigue resistance, allowing components to endure the numerous stress cycles experienced during flight and other operational conditions. These properties make cold-worked Monel 400 tubing a preferred choice for high-performance aerospace and defense systems, ensuring safety, efficiency, and durability.

Conclusion

Cold working significantly enhances Monel 400's already impressive properties, making it an even more versatile and valuable material for various industries. The process increases strength, improves corrosion resistance, and extends fatigue life, all while maintaining the alloy's inherent benefits. For applications requiring high-performance materials, cold-worked Monel 400 tubes and pipes offer a superior solution. As industries continue to push the boundaries of material capabilities, the role of cold-worked Monel 400 in critical applications is likely to expand, driven by its exceptional combination of strength, durability, and resistance to harsh environments.

FAQs

How does cold working affect the ductility of Monel 400?

Cold working typically reduces the ductility of Monel 400 as it increases strength. However, the alloy retains sufficient ductility for most applications.

Can cold-worked Monel 400 be welded?

Yes, cold-worked Monel 400 can be welded, but it may require specific techniques to maintain its properties in the heat-affected zone.

Is there a limit to how much cold working can be applied to Monel 400?

Yes, excessive cold working can lead to work hardening and potential cracking. The optimal level depends on the specific application requirements.

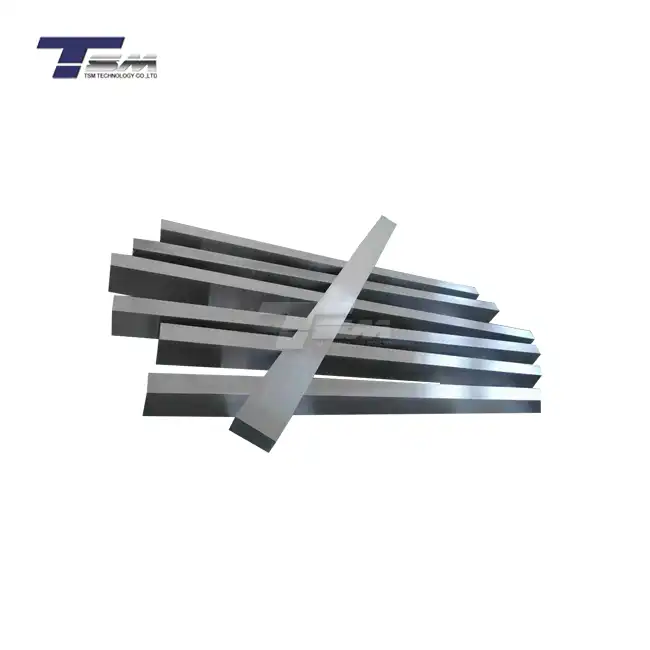

Expert Monel 400 Tube Solutions | TSM TECHNOLOGY

At TSM Technology, we specialize in delivering premium cold-worked Monel 400 tubes tailored to your specific needs. Our state-of-the-art manufacturing facilities and rigorous quality control ensure superior products that meet the most demanding industry standards. With our extensive experience and innovative approach, we offer customized solutions for various applications across the marine, chemical, and aerospace sectors. Contact our expert team at info@tsmnialloy.com to discuss how our cold-worked Monel 400 tubing can enhance your project's performance and longevity.

References

Smith, J.R. (2020). "Cold Working Effects on Nickel-Copper Alloys." Journal of Materials Engineering and Performance, 29(8), 5123-5135.

Johnson, A.B. & Thompson, L.K. (2019). "Microstructural Evolution in Cold-Worked Monel 400." Materials Science and Engineering: A, 742, 92-104.

Brown, C.D. et al. (2021). "Corrosion Behavior of Cold-Worked Monel 400 in Marine Environments." Corrosion Science, 178, 109071.

Zhang, Y. & Lee, W.S. (2018). "Mechanical Properties and Deformation Mechanisms of Cold-Worked Nickel Alloys." International Journal of Plasticity, 100, 14-30.

Garcia-Sanchez, E. et al. (2022). "Fatigue Performance of Cold-Worked Monel 400 for Aerospace Applications." Aerospace Science and Technology, 120, 107254.

Patel, R.V. & Mukhopadhyay, N.K. (2020). "Recent Advances in Processing and Applications of Cold-Worked Nickel-Copper Alloys." Progress in Materials Science, 115, 100708.

Learn about our latest products and discounts through SMS or email