Understanding Hastelloy C276 and Its Properties

Composition and Characteristics of Hastelloy C276

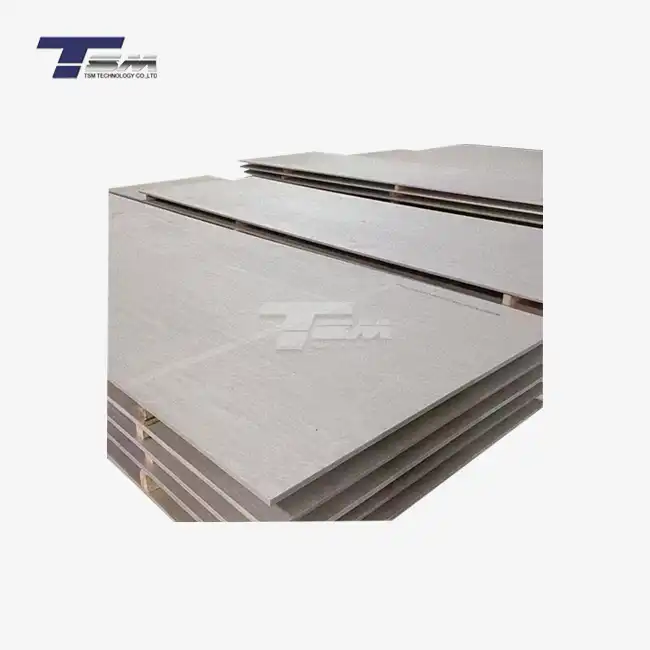

Hastelloy C276 is a nickel-molybdenum-chromium alloy renowned for its exceptional corrosion resistance. Its chemical composition typically includes 57% nickel, 15.5% chromium, 16% molybdenum, and smaller amounts of tungsten, manganese, and other elements. This unique blend imparts remarkable resistance to pitting, crevice corrosion, and stress corrosion cracking, making Hastelloy C276 tubing an optimal choice for severe service conditions.

Mechanical Properties of Hastelloy C276 Tube

Hastelloy C276 seamless pipe exhibits impressive mechanical properties, including high tensile strength, excellent ductility, and superior toughness. At room temperature, it typically demonstrates a yield strength of around 355 MPa and an ultimate tensile strength of approximately 780 MPa. These properties, combined with its corrosion resistance, make Hastelloy C276 tubing suitable for a wide range of applications in demanding industries.

Advantages of Cold Working Hastelloy C276

Cold working Hastelloy C276 tube offers several advantages. The process increases the material's strength and hardness while reducing ductility. This enhancement in mechanical properties occurs without compromising the alloy's corrosion resistance, a critical factor in its widespread use. Additionally, cold working allows for precise dimensional control and improved surface finish, essential in manufacturing high-performance components from Hastelloy C276 seamless pipe.

Common Cold Working Methods for Hastelloy C276 Tube

Tube Drawing Process

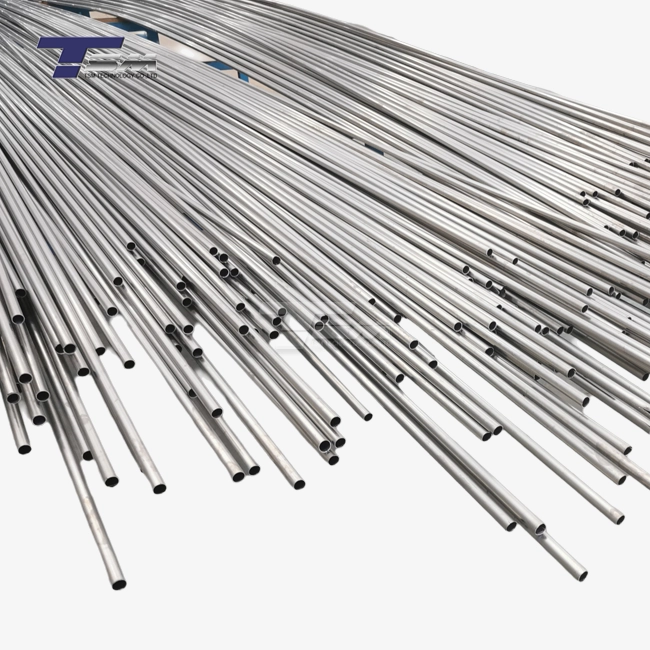

Tube drawing is a fundamental cold working method used to reduce the diameter and wall thickness of Hastelloy C276 tubing. This process involves pulling the tube through a series of dies with progressively smaller diameters. As the Hastelloy C276 seamless pipe passes through each die, it elongates and its cross-sectional area decreases. The result is a tube with enhanced strength, improved surface finish, and precise dimensional tolerances. Tube drawing is particularly effective for producing Hastelloy C276 tubing with small diameters and thin walls, often used in heat exchangers and chemical processing equipment.

Bending and Forming Techniques

Bending and forming are crucial cold working methods for shaping Hastelloy C276 tube into various configurations. These techniques include roll bending, press bending, and rotary draw bending. Each method has its advantages depending on the desired bend radius, wall thickness, and production volume. For instance, rotary draw bending is ideal for creating tight, precise bends in Hastelloy C276 seamless pipe, while roll bending is suitable for large-radius bends in thicker-walled tubing. Proper tooling and lubrication are essential to prevent surface defects and maintain the material's integrity during these processes.

Swaging and Flaring Operations

Swaging and flaring are cold working methods used to alter the end shape of Hastelloy C276 tubing. Swaging involves reducing the diameter of the tube end, often to facilitate joining or fitting insertion. This process can be performed using rotary swaging machines or hydraulic swaging tools. Flaring, on the other hand, expands the tube end to create a funnel-like shape, useful for connections and sealing applications. Both techniques require careful control to avoid excessive work hardening or cracking of the Hastelloy C276 material, particularly in thicker-walled tubes.

Optimizing Cold Working Processes for Hastelloy C276 Tube

Temperature Considerations in Cold Working

While cold working is performed at room temperature, careful temperature management is crucial when processing Hastelloy C276 tube. The material's work hardening tendency can lead to increased resistance to deformation as the cold working progresses. Controlling the temperature during the process helps maintain workability and prevent excessive stress buildup. In some cases, intermediate annealing may be necessary to restore ductility and facilitate further cold working of Hastelloy C276 seamless pipe. Monitoring and adjusting the working temperature can significantly impact the final product's quality and mechanical properties.

Tooling and Equipment Selection

Selecting appropriate tooling and equipment is paramount for the successful cold working of Hastelloy C276 tubing. Due to the alloy's high strength and work-hardening characteristics, tools must be made from materials with superior hardness and wear resistance. Tungsten carbide or diamond-coated tools are often preferred for operations like tube drawing. For bending and forming, dies and mandrels should be designed to minimize friction and prevent surface damage. Advanced CNC-controlled machinery can provide the precision and repeatability required for complex cold working operations on Hastelloy C276 seamless pipe.

Quality Control and Inspection Methods

Rigorous quality control and inspection are essential throughout the cold working process of Hastelloy C276 tube. Non-destructive testing methods such as ultrasonic testing, eddy current inspection, and dimensional measurements are commonly employed to ensure the integrity and accuracy of the cold-worked components. Surface finish inspections and hardness tests help verify that the desired mechanical properties have been achieved. For critical applications, metallographic examination and mechanical testing of sample pieces may be necessary to confirm that the cold working process has not introduced any detrimental effects on the Hastelloy C276 tubing's microstructure or performance characteristics.

Conclusion

Cold working methods for Hastelloy C276 tube offer a powerful means to enhance the material's already impressive properties. Through careful application of techniques like drawing, bending, and swaging, manufacturers can produce Hastelloy C276 seamless pipe and tubing components with superior strength, precise dimensions, and tailored shapes. The key to successful cold working lies in understanding the alloy's unique characteristics, selecting appropriate processes and tooling, and maintaining stringent quality control measures. As industries continue to demand high-performance materials for challenging environments, the ability to effectively cold work Hastelloy C276 tubing remains a crucial skill in advanced manufacturing.

Contact Us

For more information on Hastelloy C276 tube cold working methods or to discuss your specific application needs, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the right Hastelloy C276 products and processing techniques for your projects.