- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the Straightness Tolerance of Hastelloy C276 Tube?

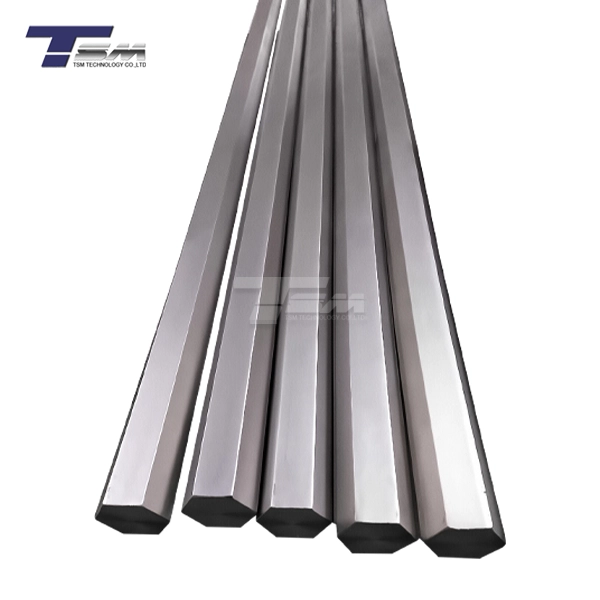

Curious about the straightness tolerance of Hastelloy C276 tube? This critical specification ensures the alloy's suitability for precision applications. For Hastelloy C276 seamless pipe, the industry standard straightness tolerance, as per ASTM B622, typically allows a maximum deviation of 0.030 inches per foot (2.5 mm per meter) for tubes with an outer diameter up to 5 inches. Larger diameters may have slightly adjusted tolerances, often specified by project requirements or manufacturer capabilities. This stringent tolerance guarantees that Hastelloy C276 tubing performs flawlessly in demanding environments, such as chemical processing or aerospace, where even minor deviations can compromise system integrity. At TSM TECHNOLOGY, our rigorous inspection processes ensure every tube meets or exceeds these standards, delivering unparalleled quality globally.

Understanding Straightness Tolerance in Hastelloy C276 Tube

Straightness tolerance is a pivotal factor in determining the quality and functionality of Hastelloy C276 tube, especially in industries where precision is non-negotiable. Delving into this concept reveals why it matters and how it impacts performance.

Defining Straightness Tolerance

Straightness tolerance refers to the permissible deviation from a perfectly linear path along the length of Hastelloy C276 seamless pipe. Measured as the maximum allowable bow or curve, this specification ensures that the tubing aligns correctly during installation and operation. A tighter tolerance translates to a straighter tube, which is crucial for applications requiring exacting fits, such as heat exchangers or pressure vessels. Industry standards, like ASTM B622, provide benchmarks, but custom tolerances can be achieved through advanced manufacturing techniques, ensuring Hastelloy C276 tubing meets specific project demands.

Why Straightness Matters in Precision Engineering?

In precision engineering, even a minuscule deviation in straightness can lead to catastrophic failures. Hastelloy C276 tube, renowned for its corrosion resistance and high-temperature strength, is often deployed in environments where alignment is critical. A tube that exceeds straightness tolerances may cause misalignment in piping systems, leading to stress concentrations, leaks, or reduced flow efficiency. In aerospace or chemical processing, such issues can jeopardize safety and performance. Ensuring strict adherence to straightness tolerances in Hastelloy C276 seamless pipe guarantees seamless integration into complex assemblies, enhancing reliability and longevity.

Measuring Straightness in Hastelloy C276 Tubing

Measuring straightness in Hastelloy C276 tubing involves sophisticated techniques to ensure accuracy. Manufacturers typically use a straightedge or laser alignment tools to assess deviation over a specified length. The tube is placed on a flat surface, and the maximum gap between the tube and the surface is measured, often expressed as a ratio, such as inches per foot. Advanced facilities, like those at TSM TECHNOLOGY, employ cutting-edge metrology equipment to verify that every Hastelloy C276 seamless pipe meets stringent tolerances, providing customers with confidence in the product's dimensional integrity.

Factors Influencing Straightness Tolerance of Hastelloy C276 Tube

Achieving the desired straightness tolerance in Hastelloy C276 tube is not a straightforward task. Several variables, from material properties to manufacturing processes, play a role in determining the final outcome.

Material Properties and Alloy Composition

The inherent properties of Hastelloy C276 tubing, derived from its nickel-molybdenum-chromium composition, influence its straightness during production. This alloy's high strength and resistance to deformation make it challenging to manipulate, requiring precise control during forming. The material's ductility, while beneficial for corrosion resistance, can lead to spring-back effects during straightening processes, potentially affecting straightness. Manufacturers must account for these characteristics to ensure Hastelloy C276 seamless pipe meets tolerance specifications, often employing specialized heat treatments to enhance workability and dimensional stability.

Manufacturing Processes and Techniques

The production of Hastelloy C276 tube involves multiple stages, each impacting straightness. Cold drawing, a common method for producing Hastelloy C276 seamless pipe, can introduce stresses that affect linearity. To mitigate this, manufacturers use straightening machines equipped with rollers or presses to correct deviations. The precision of these machines, combined with the skill of the operators, determines the final straightness tolerance. Advanced facilities also employ annealing processes to relieve internal stresses, ensuring that Hastelloy C276 tubing maintains its shape during subsequent handling and installation.

Quality Control and Inspection Standards

Quality control is the linchpin in ensuring straightness tolerance in Hastelloy C276 tube. At TSM TECHNOLOGY, every Hastelloy C276 seamless pipe undergoes rigorous inspection using state-of-the-art equipment. Inspectors measure straightness at multiple points along the tube's length, comparing results against industry standards like ASTM B622 or customer-specific requirements. Non-destructive testing methods, such as ultrasonic or laser scanning, further verify dimensional accuracy. This meticulous approach ensures that Hastelloy C276 tubing not only meets but often exceeds expectations, providing a reliable solution for critical applications worldwide.

Applications and Importance of Straightness Tolerance in Hastelloy C276 Tube

The straightness tolerance of Hastelloy C276 tube is not merely a technical specification; it directly impacts the alloy's performance in real-world applications. Understanding its role in various industries underscores its significance.

Chemical Processing and Petrochemical Industries

In chemical processing, Hastelloy C276 seamless pipe is a stalwart, thanks to its resistance to aggressive corrosives like acids and chlorides. However, straightness tolerance is crucial in ensuring leak-free connections in piping systems. Deviations beyond acceptable limits can lead to misalignment in flanges or fittings, compromising system integrity. Straight Hastelloy C276 tubing ensures efficient flow, reduces pressure drops, and enhances safety in reactors, heat exchangers, and distillation columns, making it indispensable in petrochemical plants where reliability is paramount.

Aerospace and High-Pressure Systems

Aerospace applications demand materials that perform flawlessly under extreme conditions, and Hastelloy C276 tube is no exception. In fuel lines, hydraulic systems, and exhaust ducts, straightness tolerance is critical to prevent stress concentrations that could lead to fatigue failure. A perfectly straight Hastelloy C276 seamless pipe ensures uniform load distribution, enhancing the longevity of components exposed to high pressures and temperatures. The alloy's ability to maintain dimensional stability under thermal cycling further solidifies its role in aerospace engineering, where precision is non-negotiable.

Energy Sector and Power Generation

In the energy sector, Hastelloy C276 tubing is deployed in environments ranging from nuclear reactors to geothermal plants. Straightness tolerance plays a vital role in ensuring efficient heat transfer in heat exchangers and condensers, where even minor deviations can reduce thermal efficiency. In nuclear applications, straight Hastelloy C276 seamless pipe is essential for maintaining structural integrity under radiation and corrosive conditions. The alloy's adherence to strict tolerances ensures reliable performance in power generation systems, contributing to the sustainability and safety of energy infrastructure globally.

Conclusion

The straightness tolerance of Hastelloy C276 tube is a cornerstone of its reliability, influencing its performance across diverse industries. From chemical processing to aerospace, this specification ensures precision, safety, and efficiency in critical applications. At TSM TECHNOLOGY, our commitment to quality guarantees that every Hastelloy C276 seamless pipe meets the highest standards, delivering unparalleled value to our global customers.

Contact Us

Need premium Hastelloy C276 tube for your next project? Contact us today at info@tsmnialloy.com to explore our superior alloy solutions and experience our dedication to excellence firsthand.

References

Special Metals Corporation. "Hastelloy C276: Technical Data Sheet." Special Metals Corporation, 2021.

ASTM International. "ASTM B622: Standard Specification for Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube." ASTM Standards, 2019.

Nickel Institute. "Corrosion-Resistant Alloys in Chemical Processing." Nickel Institute Publication, 2020.

International Journal of Advanced Manufacturing Technology. "Precision Straightening of High-Strength Alloy Tubes." Volume 45, Issue 3, 2018.

Materials Performance Magazine. "Dimensional Tolerances in High-Performance Alloys." Industry Report, 2017.

Energy Materials Society. "Alloy Applications in Power Generation Systems." Conference Proceedings, 2022.

Learn about our latest products and discounts through SMS or email